The University of Virginia and its partners in the Virginia Alliance for Semiconductor Technology, known as VAST, have begun a signature initiative to make the commonwealth a national leader in microelectronics innovation: the launch of the Virtual Fabrication Access Bridge.

VFAB is a statewide platform, believed to be the first-of-its-kind in the U.S., that makes high-end semiconductor fabrication tools more accessible for researchers, educators and industry partners by linking more than 170 advanced instruments across VAST’s partner universities: UVA, Virginia Tech, Virginia Commonwealth University, Norfolk State University, George Mason University, and a new addition, Old Dominion University.

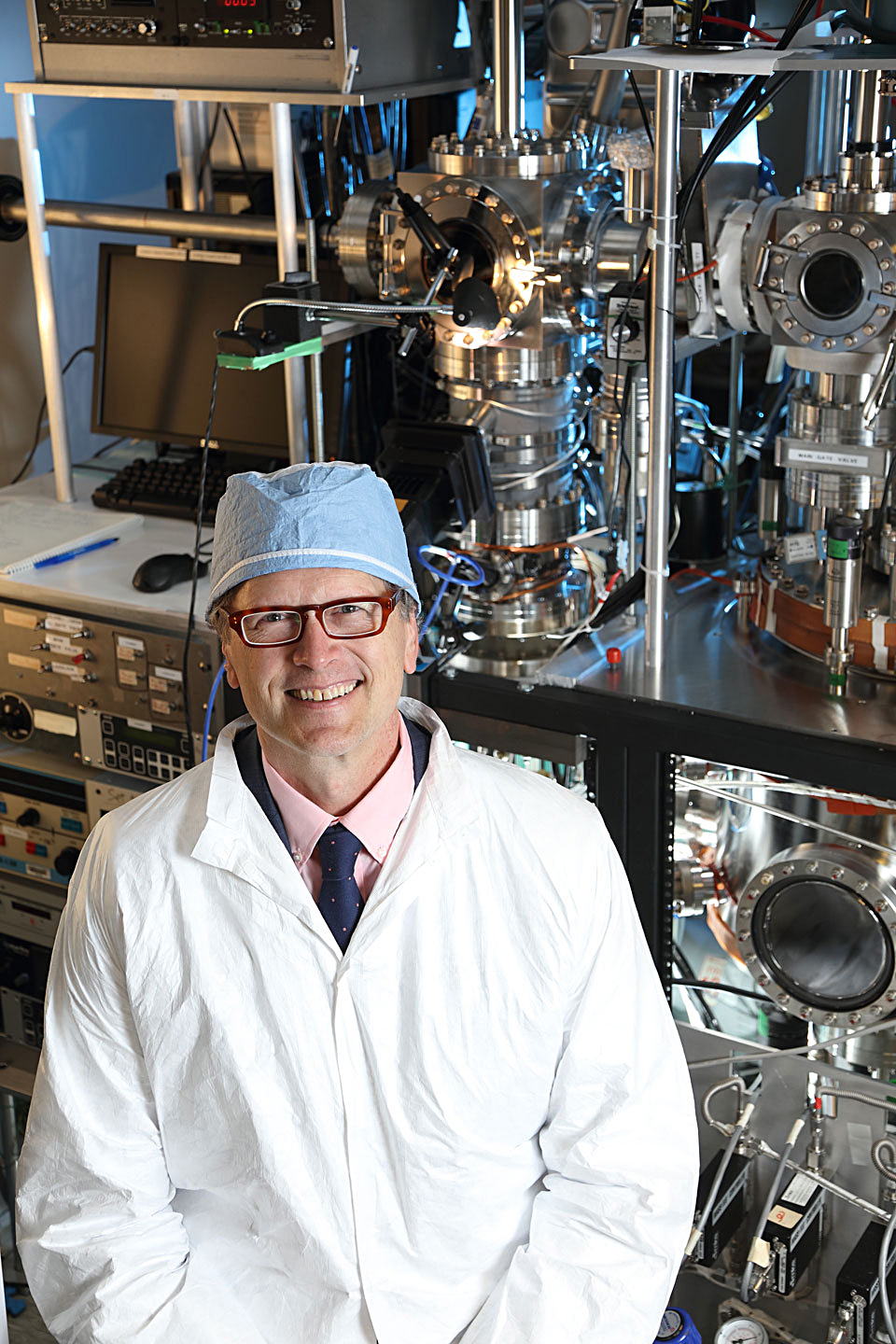

“VFAB’s unified access model lowers longstanding barriers in microelectronics research — particularly for students, startups, institutions, even large companies that don’t have the needed fabrication infrastructure,” said Arthur W. Lichtenberger, a research professor in UVA’s Department of Electrical and Computer Engineering, who was a key contributor to the creation of VAST and one of the visionaries behind the VFAB platform.

VFAB’s unified access model lowers longstanding barriers in microelectronics research.

VFAB also raises awareness throughout the state’s semiconductor community of the resources that are available in Virginia, said Swarnanjali Bose, VAST process engineer based at UVA who helped build the VFAB platform. Each participating university catalogs its inventory of tools with specifications and capabilities clearly listed.

“We are showcasing our tools through VFAB,” Bose said, “It’s unique. It gives us an advantage in semiconductor research that our users can enter this platform and readily see which partner university, or combination of partners, best suits their fabrication needs.”

“Moreover,” she added, “since we all collaborate under VAST, becoming a registered user and accessing multiple facilities is streamlined and efficient.”

How VFAB Works

Built using Facility Online Management software — an internationally adopted utility for managing scientific instrumentation — VFAB offers a single, cloud-based facility reservation, training and fee platform. This infrastructure makes the platform maintainable, fosters collaborations and enables resource sharing. For facility administrators, the software keeps track of when equipment is used, for what purpose and by whom — data that is invaluable to their own maintenance schedules, administrative processes and budgetary planning.

For example, two facilities under Lichtenberger’s direction, the Innovations in Fabrication and Nanoscale Materials Characterization Facility, called IFAB and NMCF respectively, participate in VFAB. Platform users can see what each lab houses, reserve time to use instruments they need and request training or assistance from the instruments’ managers, who are identified on the VFAB platform.

VAST — A Transformative Alliance

The Virginia Alliance for Semiconductor Technology, and its initiatives like VFAB, supports national priorities identified in the CHIPS and Science Act and responds to federal calls for broader access to semiconductor fabrication and workforce training.

Backed by the Virginia General Assembly, the alliance has three foundational pillars.

The first establishes a coordinated network of semiconductor and nanofabrication cleanrooms and facilities for characterization (measuring and describing a material’s physical properties) and advanced packaging (the final step in chip fabrication) across member institutions that is open to the user community.

The second aims to accelerate the development of a qualified semiconductor workforce through VAST’s Fast Track to Semiconductor Careers certificate program.

The third is to serve as the gateway to semiconductor and nanotechnology industry and excellence in the commonwealth.

UVA Engineering Was Poised To Chip In

UVA’s IFAB and NMCF facilities both operate on a principle similar to VFAB by making high-end instrumentation available to qualified community users across and beyond UVA. Availability can mean for direct use or, in some cases, as a service performed by facility staff. Examples of UVA’s equipment include the:

Raith 150 E-Beam Lithography System: Used to “write” structures smaller than viruses, with single-digit nanometer precision, critical for photonic devices and quantum research

Themis 60–300kV Transmission Electron Microscope: Captures atomic-scale images of materials — essential for battery research, chip materials and failure analysis

Oxford ICP-CVD PlasmaPro 100 Cobra 300: Produces exceptionally high-purity thin films in a diverse range of materials. Thin films are essential for making integrated circuits, transistors, optical filters and much more.

Quanta 650 SEM: A powerful imaging tool capable of inspecting microchips and materials at magnifications up to 1,000,000x.

These are just a few of the instruments made available to VFAB users, Bose said: “At UVA alone we have more than 75 tools integrated — and each one opens doors for researchers who previously couldn’t access them.”

UVA was primed to contribute to VAST and VFAB thanks to the evolution of the IFAB and NMCF, which began as faculty members’ labs — Robert Mattauch and Ken Lawless respectively — in the late 1960s, Lichtenberger said.

IFAB focuses on interdisciplinary research combining micro- and nanofabrication, biosensing and additive manufacturing to develop next-generation biomedical and electronic devices. The NMCF characterization facility provides advanced microscopy, spectroscopy and surface analysis tools for characterizing materials at the nanoscale, supporting research in nanotechnology, materials science and semiconductor processing.

Both labs grew, diversified their equipment portfolios and expanded their users to more than 300 — including Ph.D. students, postdoctoral scientists, and researchers from government and corporate labs — between them. IFAB and NMCF eventually transitioned to department-wide and, more recently school-wide, user facilities, but researchers around the world have sought their expertise for years.

I’m excited that we’re adding training to our IFAB repertoire.

“IFAB and NMCF were not created with the thought of someday creating a VAST-like entity, which originated organically between faculty leaders from the universities involved,” Lichtenberger said. “IFAB and NMCF have both served internal and external communities for decades; VAST is allowing us to do so in a more structured and enabling environment.”

VAST is also expanding IFAB’s reach through the Fast Track to Semiconductor Careers certificate program, said electrical and computer engineering department chair Scott Acton, the American Telephone and Telegraph Company Professor of Engineering.

“IFAB has always been a place where cutting-edge research in semiconductors has been realized,” Acton said. “With the VAST program, I’m excited that we’re adding training to our repertoire. IFAB is training the next-generation semiconductor workforce. These trainees are now in the clean room, learning the concepts and techniques needed to prototype, manufacture and test state-of-the-art chips.”