Data Acquisition & Cameras

Data Acquisition

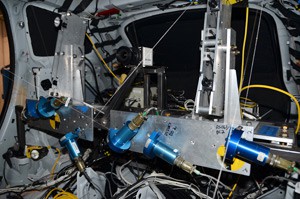

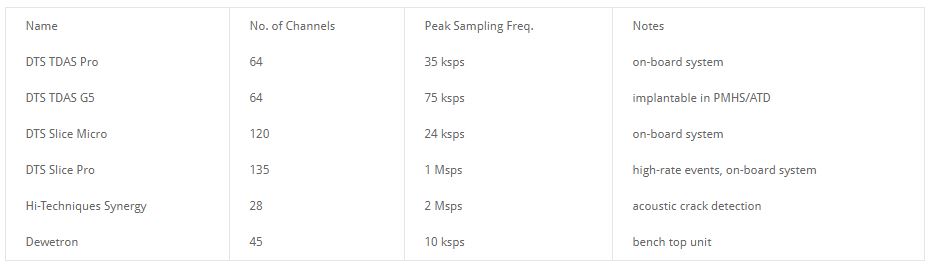

CAB has multiple data acquisition systems, with a range of sampling frequencies and applications for the challenging environments of PMHS testing (Table 1). Some systems can be on-board the impact devices, and some can be implanted in the test specimens. Some high-speed devices can readily record wave propagation and acoustic crack detection events. The CAB maintains an extensive inventory of over 500 calibrated sensors dedicated to biomechanical research. The most commonly used sensors are piezo-electric accelerometers, single and multiaxial strain gauge load cells, magnetohydrodynamic (MHD) and micro-electromechanical (MEMS) angular rate sensors, pressure transducers, acoustic crack detection sensors, and potentiometers measuring displacements or angles. Customized instrumentation packages are also configured by CAB personnel.

Cameras

CAB maintains photogrammetry and imaging equipment with wide ranging capabilities including ten NAC Memrecam GX1, an ultra-light sensitive 1.3 million pixel camera, two NAC Memrecam GX5 systems, including a high-resolution camera and eight micro cameras for onboard video capture, two Phantom v5.0 Cameras that can record at 3,800pps, and four Kodak HG and RO Imagers that can capture up to 2000 full video frames per second at a resolution of 512 X 384 pixels. All these cameras are hardened for use on the crash sleds.

3D Optical Measurement Systems

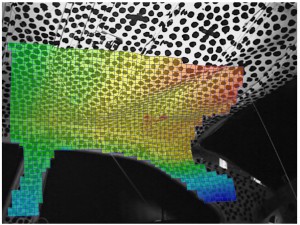

ARAMIS is a non-contact measuring system, which is well suited for measuring three-dimensional deformation and strain distributions of biological specimens under static or dynamic load. ARAMIS records an object under load using CCD cameras. For each stage of load, the 3D coordinates of the object surface are calculated on the basis of digital image processing delivering also the 3D displacement and the surface strain. The dimensioning of specimens, the exact determination of material properties and the improvement of FE calculation models are possible using the ARAMIS system. Previous applications of the system at the CAB include strain field measurement in both hard and soft tissues.

The CAB utilizes a state-of-the-art 46-camera 1000 Hz high-rate video-based optoelectronic stereo photogrammetric system (Vicon MX, Vicon, Los Angeles, CA), more commonly referred to as a motion capture system. The overall 46-camera system is actually comprised of four separate stand-alone systems that operate in a modular configuration allowing the CAB to combine the systems into one large 46-camera system when necessary. Conversely, the system can be divided into four separate stand-alone systems to support multiple projects occurring simultaneously when necessary. The system is capable of tracking the retro-reflective targets with an accuracy of ± 1 mm or less.