Research

Novel microfluidic devices, circuits and signal analysis systems for label-free biophysical stratification of the heterogeneity in biosystems for precision medicine applications.

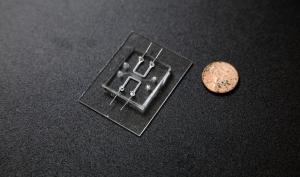

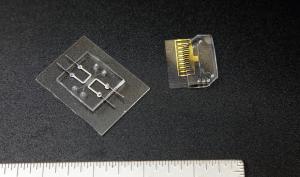

- Microfluidic separation and biophysical phenotypic analysis with single-cell sensitivity: Stratifying the phenotype of cells, multi-cell aggregates, bacteria, and extracellular vesicles based on biophysical metrics (electrophysiology and deformability). See example (publications) for analysis of single-cells (Anal Chem (2017) 89, 5757–5764 and Anal Chim Acta (2020) 10.1016/j.aca.2019.12.033), bacteria (Sensors & Actuators B: Chemical (2018), 276, 472-480 and ACS Infectious Diseases (2016) 2 (8), pp 544–551), extracellular vesicles (Analytical Chemistry (2019) 91, 10424-10431) and multi-cell aggregates (Lab Chip (2017) 17, 3682 – 3691)

- Nano-confined platforms for biomolecular sensing: Nanoscale confinement enables near instantaneous diffusion and novel sensing mechanisms based on redox amplification. We integrate biosensing modality within confined material and fluidic structures for evaluation bacterial constructs in synthetic biology and for screening of biorecognition receptors. See example publications: Nanoscale (2017), 9, 12124-12131; Electrochem Comm (2016), 72, 144-147; Biosens. Bioelectron. (2016), 78, pp. 244-252; Lab Chip (2015), 15, 4563 – 4570) and redox amplification (Electrochimica Acta (2019), 318, 828-836);

- On-chip integration of sensing, signal analysis & microfluidic isolation: Control circuits for electrokinetic (IEEE Trans Bio-medical Eng (2020) 67, 1664-1671) and acoustic trapping (Micromachines (2019), 10 (7), 489), as well as neural network-based recognition (Anal Bioanal Chem (2020) 412:3835–3845) and data analytics

- Microfluidic biofabrication for in vitro disease models: To develop in vitro tissue, disease and organ-on-chip models that mimic in vivo microenvironment, transport and paracrine signaling cues, we specialize in microfluidic and lithography-based methods to construct core-shell perfusable cell-laden hydrogel platforms

LAB - space of 700 sq. ft. (250 sq ft clean room)

Microsystem Fabrication

Instrumentation for Microsystem Fabrication in Wilsdorf Hall B007 (Class 10000 Clean Room) includes various soft material patterning tools (Direct-Write UV Laser Lithography; Imprint Lithography and Hot Embossing), polymer deposition (UV-visible photo curing of cells in hydrogels) and etching tools, as well as profilometry-based imaging of high aspect ratio polymeric structures.

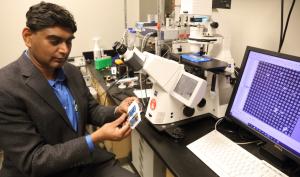

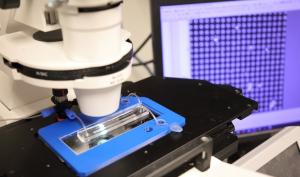

Microfluidic Separation

For microfluidic separation, the group has: (i) Two Zeiss inverted microscopes with EMCCD and CMOS imaging systems; (ii) 4-channel pressure-based flow control (Elveflow & Fluigent); (iii) Multi-channel Syringe Pumps (Cetoni & Harvard Inst); (iv) Zurich Instruments and Amphasys Impedance Analyzer Systems for Single-Cell Cytometry; (v) Beckman Coulter Flow Cytometry System; (vi) 3DEP Analyzer

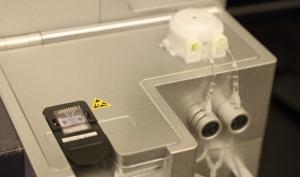

Microfluidic Sensing and Biofabrication

For microfluidic sensing, the group has: (a) flowthrough platforms for voltametric sensing; (b) separation and impedance cytometry tools at channel outlets; and (c) redox amplification methods on biofabricated redox capacitors

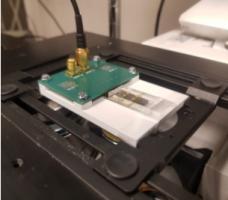

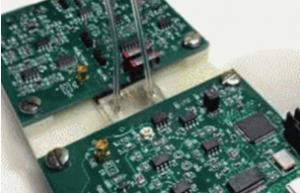

Biomedical Circuits and Signal Processing

Our group has developed various customized circuits and tailored signal processing methods. IEEE Trans Biomed Eng 2020 67 (6) : Research Highlights https://ieeexplore.ieee.org/abstract/document/8844818