Facilities

The Environmental Cracking Laboratory at the University of Virginia is a state-of-the art facility that allows users to combine high-fidelity fracture mechanics testing with real-time immersion in the environment of interest. In addition to our outstanding mechanical testing capabilities, our laboratory is equipped with other unique features ranging from a surface science quality vacuum system to controlled temperature testing.

Burns Research Group Lab Tour

Dr. Zach Harris leads the viewer through the Burns Research Lab, covering some of the major testing equipment in the lab and the testing that is currently being implemented.

Experimental Equipment and Techniques

Environmental Testing

The ability to test specimens immersed in their projected service environment is critical to the development of safe and reliable components. The Environmental Cracking Laboratory offers the ability to conduct testing in many types of relevant environments, including:

- Ultra high vacuum (up to 10-9 torr) with the capability to introduce a known water vapor pressure and low temperature so as to allow for the simulation of flight conditions at high altitude

- Two high temperature testing furnaces for different testing geometries

- Two high temperature testing furnaces for different testing geometries

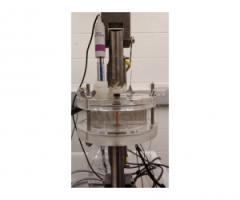

- Numerous Plexiglass cells to immerse specimens in aqueous and gaseous environments during testing

- Numerous potentiostats for the simulating environments in which electrochemistry is pertinent

Mechanical Test Frames

With a total of eight mechanical testing frames, the Environmental Cracking Lab has the breadth and depth to conduct testing in all sorts of environments. While some frames are utilized for particular types of testing (i.e. the ultra high vacuum system), most of our frames are able to run the full swath of testing required for characterized environmental effects. Our equipment was recently upgraded by the addition of a new pump, two new controllers, and new control software. We also collaborate with faculty in the Civil Engineering Department and at the Virginia Transportation Research Council, which provides access to additional frames if needed. With unique capabilities like a mountable furnace and high-fidelity crack growth monitoring on every frame, the Environmental Cracking Lab stands out!

High Fidelity Testing and Control

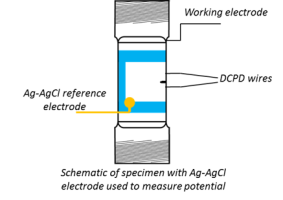

There is an old adage in the research community: "Your data is only as good as the system used to collect it." In our case, we need highly precise data collection capabilities to enable our unique slow-rising stress intensity testing. For example, to control a test by stress intensity, you need to have a precise measurement of crack length, otherwise your command will be incorrect. To achieve this difficult measurement, the Environmental Cracking Lab has developed expertise in utilizing direct current potential difference (dcPD) to evaluate crack lengths with 0.5 micron accuracy. We use Fracture Technology Associates's (FTA) software to automate these calculations and send the required commands to the MTS Station Manager software which then communicates with the load frame itself. A second factor that must be accounted for, especially when fatigue testing specimens, is crack closure. Thankfully, FTA's software also allows us to attack this by either the ASTM 2% Offset or the ACR method. All in all, the combination of FTA and MTS allows us to exert extensive control over our testing, thereby ensuring high fidelity data collection and accurate results.

As stated above, we often test our specimens using slow-rising stress intensity, but we can also use slow-rising displacement when needed. We also have the capability to conduct standard fatigue testing, tensile testing, and other typical fracture mechanics experiments.

Additional Capabilities and Expertise

Research in the Center for Electrochemical Science and Engineering (CESE) allows graduate students to both collaborate with the top minds in electrochemistry and have access to one of the world's premier electrochemistry laboratories. This unique opportunity provides significant advantages when it comes to environmental testing as the CESE labs are equipped with an impressive array of technology, including:

- UV accelerated testing equipment

- Two Q-FOG environmental chambers

- Thermal desorption spectrometer (TDS)

- Raman spectometer

- Scanning Kelvin Probe (SKP)

Futhermore, the Materials Science and Engineering has faculty who can provide access to furnaces for heat treating, help with computational modeling, and other types of expertise that will assist you in your research.