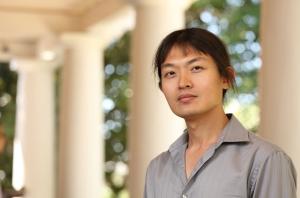

Ji Ma, an assistant professor of materials science and engineering at the University of Virginia School of Engineering and Applied Science, has received a Commonwealth Commercialization Fund grant to help move his wrist replacement technology into the marketplace. Ma’s innovation could enable arthritic patients to regain movement and use their joint normally with less discomfort and financial burden than current treatments.

The Virginia Innovation Partnership Corporation (VIPC) announced the $100,000 award on Jan. 22.

Wrist arthritis is a common and debilitating condition affecting more than 13% of the U.S. population. Unlike the knee or hip, the wrist is not conducive to joint replacement because of high failure rates.

The wrist is the only major joint in the human body without a permanent motion-preserving surgical treatment option.

Instead, patients are encouraged to cope using non-operative management tactics until the pain and swelling become significant enough that they are willing to undergo surgery to partially or completely fuse the wrist, a procedure that provides relief from pain but permanently sacrifices wrist motion.

Ma, alongside his collaborator Brent DeGeorge of the University of Virginia Department of Plastic Surgery, has created a total wrist replacement system inspired by the beak of a squid, which gradually changes in stiffness throughout its structure, eliminating stiffness mismatch and excessive stress.

Overcoming Obstacles to Joint Replacement

Made with titanium that is flexible, aligns with bone movement, and mimics actual bone stiffness gradients, Ma’s 3D-printed implant solves for frequent failures due to bone erosion and implant loosening that has prevented wider adoption of wrist replacement to date.

“The wrist is the only major joint in the human body without a permanent motion-preserving surgical treatment option. There is a clear need for an improved solution beyond pain management and joint fusion for those suffering from arthritis in the wrist,” Ma said.

“We’re excited to be developing a long-term option that addresses the shortcomings of current treatments and offers permanent pain relief akin to total knee, hip and/or shoulder replacements by reducing excessive stress on the bone.”

Joe Benevento, VIPC president and CEO, said, “R&D commercialization is thriving in Virginia thanks to unique collaborations and advancing technologies across our colleges and universities. VIPC is pleased to support Dr. Ma and team as they bring to market an innovative product solution that serves a $1.7 billion healthcare segment and can significantly improve the quality of life for arthritic patients.”

The CCF grant will help Ma and team complete a thorough customer discovery process, generate “knock-out” data to build a persuasive case for surgical early-adopters, formulate a credible FDA 510(k) strategy, and establish a surgeon advisory group to carry out the first human trials of the implant. The team’s goal is to have a commercially ready product on the market within four years.

About VIPC

VIPC operates as the nonprofit corporation on behalf of the Virginia Innovation Partnership Authority (VIPA) to help lead innovation and economic development in Virginia. Learn more about VIPC programs, including the Commonwealth Commercialization Fund, at VIPC.org.