John A. Rogers pioneered the first bioelectronics for human skin: a thin bandage-like device with embedded microelectronics. Rogers is a cross-disciplinary engineering professor at Northwestern University who holds more than 100 patents, most of which have health care applications. He delivered the inaugural Jefferson Engineering Lecture at the University of Virginia on May 2, sponsored by the Jefferson Trust and the School of Engineering and Applied Science.

The lecture’s goal is to bring pioneering research ideas that cross traditional boundaries to UVA students and faculty. Rogers spoke to the large audience gathered at Newcomb Hall about the innovations propelled by his research group’s technologies over the past decade to present.

A partial list of the Rogers group’s breakthroughs in personalized medicine includes enabling more precise robotic limbs; creating wireless neo-natal intensive care units in which soft, flexible sensors monitor babies’ vital signs; and even creating those Gatorade sports patches used by famous athletes.

“My own interest is more in medicine, rather than sports,” he noted. But in the same spirit that UVA helps its professors turn their research into entrepreneurial efforts, Rogers said he too appreciates the full “application opportunities” his lab makes possible.

Wireless Health Monitoring

The Rogers group specializes in its ability to use polymers, liquid crystals and biological tissues — alone or in hybrid combinations — with unusual classes of inorganic micromaterials or nanomaterials that can be fashioned into engineering components such as ribbons, wires, membranes and tubes.

One cross-disciplinary application has been wireless, in-hospital patient monitoring, which can lower costs, enhance patient comfort and improve data access for health care professionals.

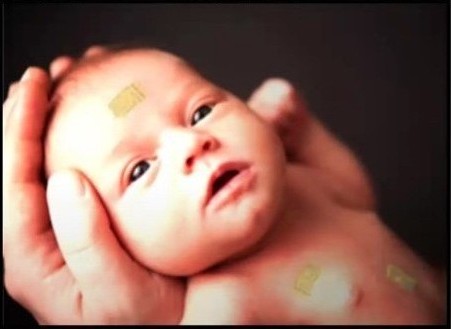

In research sponsored by the Gates Foundation, Rogers’ team developed wireless newborn and infant health monitoring patches that could withstand hundreds of cycles of reuse, resulting in an average cost of 10 cents per patient.

He said a spinout company inspired by such breakthroughs is now implementing its wireless monitoring strategy for patients in all of the hospitals in Denmark.

The devices, based on technology he first pioneered at Northwestern Children’s Hospital, can be used on newborns delivered as prematurely as 26 weeks gestation, or “about as small as you would see in a NICU.”

Improving Life for Amputees

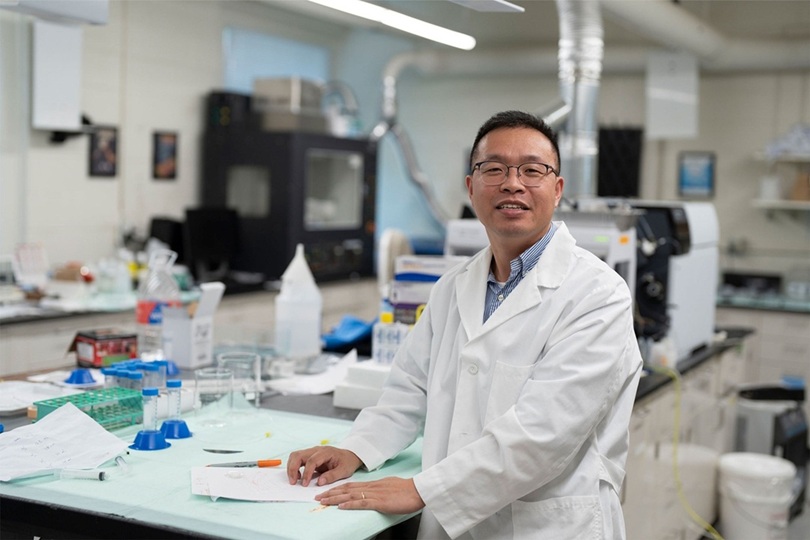

Baoxing Xu, a professor in UVA Engineering’s Department of Mechanical and Aerospace Engineering, administers the new lecture series, in association with committee members from UVA’s Electrical and Computer Engineering, and Materials Science and Engineering departments, as well as the schools of Data Science and Medicine.

Rogers’ visit was personally meaningful for Xu. Prior to Rogers joining Northwestern, Xu worked with him as a Beckman Postdoctoral Fellow at the University of Illinois at Urbana-Champaign, from 2012 to 2014.

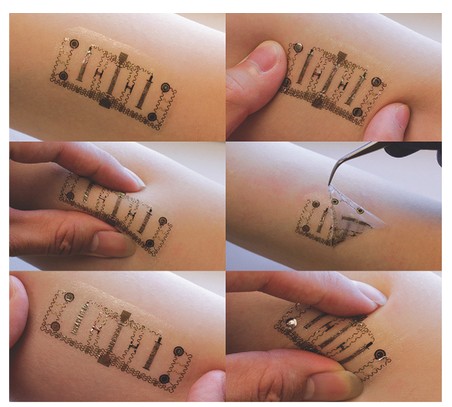

It was in Rogers’ lab that Xu developed a multipurpose electronics platform for the skin that worked using stimulation and sensors.

One of the application demonstrations for the tech was to show how it could help amputees.

One of the challenges [the veteran] had is he liked to hold his daughter, but he didn't want to crush her with his robotic hand.

The team reported in an Advanced Materials article that control of a robotic arm could be improved by using nerves in an operator’s own upper arm, in combination with the lab’s specially configured skin patch. That’s important because surgeons relocate key nerves as part of amputation. But the degree to which those nerves can be useful in operating a robotic prosthesis depends heavily on how fine the electronic contact points are that reach the nerves. Sensors, which can receive tactile information, and actuators, which can apply force, must be able to work together in a space that’s sometimes as small as a typical Band-Aid.

In tests, the blindfolded operator manipulated the robotic arm successfully; the machine didn’t crush the plastic bottle in its grasp.

Rogers has continued to improve upon the device to help an Iraq War veteran who lost his arm from the elbow down.

“One of the challenges [the veteran] had is he liked to hold his daughter, but he didn't want to crush her with his robotic hand,” Rogers said.