In 2021, there is worldwide concern over semiconductor shortages. So imagine if a technology existed to roll sheets of semiconductor materials off a printing press like the daily edition of The Wall Street Journal.

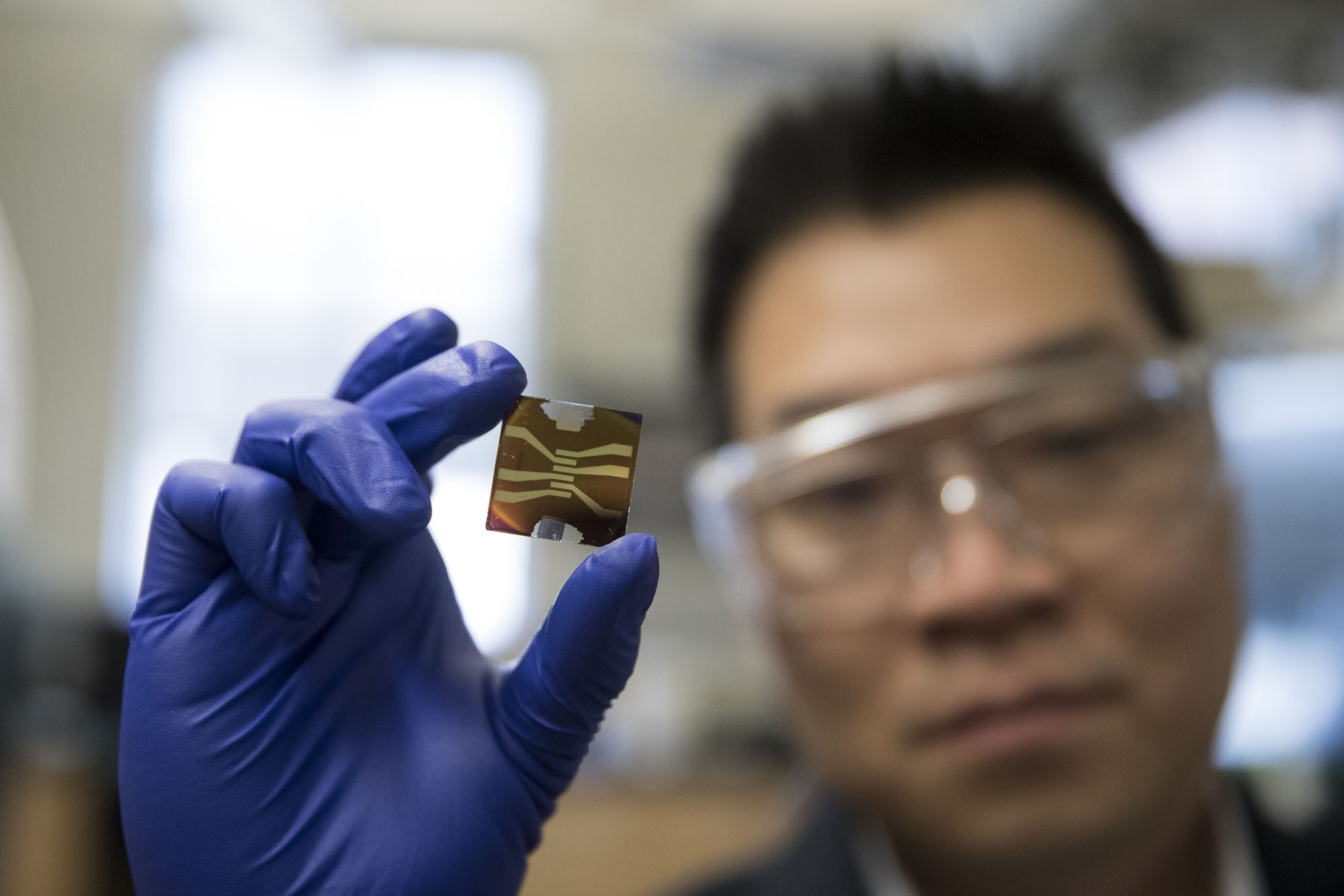

Joshua Choi, an associate professor of chemical engineering at the University of Virginia School of Engineering and Applied Science, believes such a scenario is possible. He is working with a group of researchers led by Cornell University, his Ph.D. alma mater, under a $3 million U.S. Department of Energy grant to use machine learning to accelerate the development of low-cost, easy-to-manufacture semiconductor materials for solar energy. Choi’s lab will play a pivotal role in manufacturing and performance-testing photovoltaic cells fabricated with a class of semiconductor materials called hybrid organic-inorganic perovskites.

Perovskites are crystal structures that can efficiently convert light into electricity, making the material an attractive semiconductor for solar cells — that, and the ability of hybrid organic-inorganic perovskites to grow in a solution.

“We can make the entire device from a simple ink processed at a low temperature,” Choi said. “You pretty much coat it on a substrate and turn it into a photovoltaic cell.”

Partners on the three-year project, “Formulation Engineering of Energy Materials via Multiscale Learning Spirals,” are principal investigator Lara Estroff, professor of materials science and engineering at Cornell, and co-principal investigators John Marohn, professor of chemistry and chemical biology at Cornell; Paulette Clancy, professor head of the Department of Chemical and Biomolecular Engineering at Johns Hopkins University, and Rigoberto Hernandez, Gompf Family Professor of Chemistry at Johns Hopkins. Additional collaborators are researchers from Lawrence Livermore National Laboratory and Pacific Northwest National Laboratory and Cornell alumni David Moore of the National Renewable Energy Laboratory, with whom Choi’s lab is working in close coordination.

A conventional silicon solar cell requires careful processing and extreme heat to produce a high-quality crystal, which is expensive and consumes a lot energy. Today’s solar panels are also heavy and rigid.

“What if instead of having to install silicon solar cells on your rooftop at high cost and hoping to get your investment back after several years, you can pick up cheap, lightweight sheets from Home Depot or Lowe’s and roll them out over your roof yourself?” Choi said. “Or you could use the material to power a campsite. If cells need to be replaced, you can buy more because they’re inexpensive and easy to install. That’s the dream.”

The reality is that perovskites, while easy to fabricate with enticing efficiency rates on small devices in the lab, perform unreliably and work for only a short time when scaled to real-world dimensions.

“There are a lot of processes we don’t understand and cannot yet control well,” Choi said of the way atoms form into a perovskite crystal, how the crystal behaves in a solar cell and how the entire cell performs.

Making perovskites reliable, stable and scalable is a matter of finding the right ingredients and steps for processing them, Choi said. But there are half a million possible atomic compositions the researchers can try — plus solvents, additives and temperature variations to test.

“Random searching in such a large parameter space would require an almost infinite number of hours and dollars for experimentation, so it’s not practical,” Choi said. “That’s why we’re teaming up with machine learning experts. They’re going to orchestrate the effort based on their machine learning algorithm with the aim of drastically accelerating the optimization process.”

A confluence of research breakthroughs by members of what Marohn called a dream team in a Cornell news release provided the optimism for solving these challenges. Estroff is a leading expert in crystallization. Her lab’s observations on perovskite precursors made researchers wonder if they could steer how perovskites crystallize to improve stability.

“The lab’s work with Clancy found they could compute how the precursors form in different solvents, which suggested a possible role for large-scale machine learning to predict material synthesis,” the Cornell release said. “Marohn’s group showed, by measuring the material’s electronic properties, that when light is shined on perovskites, not only are electrons knocked loose, triggering electronic conductivity, but so are ions. The ionic conductivity could be one reason why the material has been unstable.”

Choi’s lab will augment Estroff’s crystallization studies, but his biggest responsibility, along with Moore — also a leader in building and testing perovskite solar cells — is fabricating and performance testing all of the solar cell devices for the project. Choi believes using the machine learning predictions to select their experimental parameters makes it possible to eventually see inexpensive, do-it-yourself solar arrays on store shelves. That is the promise of perovskites.

“With a few days of training, undergraduate students can make solar cells in our lab easily,” Choi said. “Understanding how these materials behave is the difficult part. But once you understand them and can rationally tune the composition and processing conditions, it will be like developing a recipe for a new dish. After that, it will be easy for many people to just follow the recipe to come up with delicious dishes everywhere.”