Training & Documentation

This section outlines training, laboratory signage and other documentation requirements and resources.

Training

- Required Training- University faculty, staff, and students who are required to complete Chemical Safety Training must complete at least one of the following training modules (or have properly documented completion of analogous training) to be considered in compliance with University policy. Laboratories, Departments, or other groups may schedule an in-person “live” Chemical Safety and Waste Training session by calling EHS at 434-982-4911.

- Chemical Safety and Waste Training for Research Personnel & Students -Required training for Research Personnel & Students who work in a laboratory/area where chemicals are used, or who generate Hazardous (Chemical) Waste.

- Chemical Safety and Waste Training for Non-Research Personnel-Required training for Non-Research Personnel who work in a laboratory/area where chemicals are used, or who generate Hazardous (Chemical) Waste.

- Chemical Safety Training for Support Staff -Required training for persons who do NOT handle chemicals, but who may be accidentally exposed to chemicals.

- Site-specific hazard training shall also be given by Principal Investigators or lab/space managers on site-specific chemical hazards, i.e., personnel are given an understanding of the specific hazards they may be exposed to, how to safely handle, protect themselves to minimize risk of exposure, and proper disposal of the specific chemicals. Lab occupants should complete applicable training prior to working in the lab.

- Annual Safety Seminar – a department wide ‘safety seminar’ is held each year to provide an annual refresher and recap on important changes to the department’s safety agenda. Attendance is mandatory for all CHE faculty (including part-time faculty), staff, and graduate students.

- Other training will depend upon other work protocols (Institutional Biosafety Committee, Animal Care and Use Committee, Radioactive material, etc.), or specialized needs (shipping dry ice). EHS has also developed a wide range of recommended trainings that faculty and lab managers will find helpful for further safety awareness in the lab.

- Online safety training modules are also available for other laboratory subjects, including Chemical Storage, Compressed Gas Cylinder and Regulator Safety, and Handling Organolithiums and Related Agents. Available training can be found at https://researchcompliance.web.virginia.edu/training_html5/modules-ehs.cfm

- The Safety, Training, and Recordkeeping (STAR) system on the EHS website can be used to document training provided locally in laboratories and other work units.

Signage and Other Documentation

- Lab Occupant Information- All laboratories must display updated lab occupant’s information with contact information to be used in case of emergencies. A sample information form can be found in Appendix A.

- High Hazard Unattended Equipment – Any equipment or experiment that is operated unattended for any length of time and requires either special shutdown procedures or warnings about unusual hazards must display an Emergency Notification form (Appendix B).

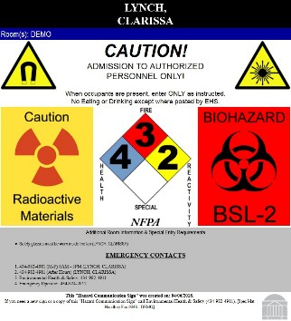

- Hazard Communication Sign -As required by regulation and for the benefit of UVA personnel, outside contractors, emergency personnel, or other visitors to an area, UVA posts a Hazard Communication Sign on all laboratory, shop, studio, and makerspace doors, and other select room doors where hazardous materials may be present. Laboratories should periodically review this signage and work with EHS to make necessary updates. Posting and maintaining the Hazard Communication sign is a responsibility of UVA EHS.

- The Hazard Communication Sign will display through symbols, icons, and text which types of hazards (e.g., biological, radiological, chemical, or non-ionizing radiation) are potentially present beyond the door. The sign will also list PI(s) and emergency contact information. The potential hazards in the space may provide direction on personal protective equipment (PPE) or other safety precautions that are required for entry.

- Safety Data Sheets (SDS) The Occupational Safety and Health Administration (OSHA) Hazard Communication Standard (HCS) requires that employees be provided information about the physical and health hazards of the chemicals they use or are potentially exposed to in their work area.

Safety Data Sheets (SDS) are the primary communication tool that provides the most basic, essential information about a hazardous substance or mixture. Federal law requires that an SDS for all of the hazardous chemicals used at a location must be readily accessible to employees. These sheets provide detailed information and precautionary measures for the handling of chemicals and solvents.

SDS can be found on a searchable database on the EHS website, Ehs Chemical Safety SDS