Shape Memory Alloys

Shape Memory Alloy Materials

Shape memory alloys (SMAs) have attracted a great deal of attention as a smart material that can be used in various civil engineering applications. Our research group aims at the development and characterization of SMA materials to accelerate the implementation of shape memory materials in real world structural applications.

SMA Cables

SMA cables consist of several strands laid helically in one or more layers around a core. The strands themselves have a center wire around which thin SMA wires are wrapped helically. SMA cables exploit the excellent mechanical properties of thin wires to resist large axial loads. We characterize the mechanical response of SMA cables under various cyclic amplitudes and loading frequencies and study their fatigue properties.

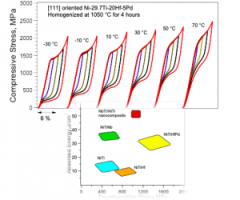

High Performance SMAs

This research explores new SMAs with larger energy dissipation capacity over a large temperature range for structural application. In particular, NiTiHfPd SMAs, which shows perfect superelastic response with 6% strain and no permanent plastic deformation under compressive loads up to 2.5 GPa and has a superelastic temperature window of 100˚C, are extensively chracterized.

Buckling Response of SMA Bars

Despite a handful of experimental data on the buckling behavior of SMA bars exists in the literature, lack of better understanding inevitably brings uncertainties when SMA bars are used in a structural engineering application and subject to compression. To address this knowledge gap, this study investigates the buckling and post-buckling behavior of large-diameter superelastic NiTi SMA bars.

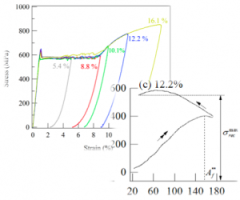

Shape Memory Effect SMAs

SMAs that exhibit shape memory effect (SME) generate large residual deformations when the material is mechanically loaded over a certain stress level and unloaded. However, the SME SMAs recover those residual strains upon being heated. This research investigates wide hysteresis SME SMAs for civil engineering applications.

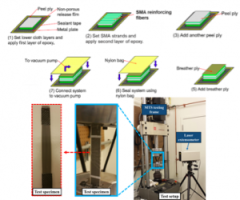

SMA FRP Composites

Conventional FRPs exhibit brittle failure at relatively low ultimate tensile strains, low toughness, and limited fatigue strength. This research explores the development of composite materials that consists of a thermoset polymer matrix reinforced with superelastic NiTi SMA fibers. We study the monotonic, cyclic and fatigue behavior of the developed superelastic SMA FRPs.

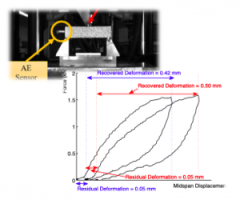

SMA Fiber Reinforced Cementitious Composites

The use of SMAs in cementitious composites as fibers can enable crack recovery and re-centering capabilities. This study explores the crack recovery characteristics of SMA fiber reinforced cementitious composites, including both mortars and concrete, under flexural cyclic loading. We use digitial image correlation (DIC) and acoustic emission analysis to study crack formation, propogation and recovery.

Related Publications

- Kilic, U., Sherif, M., Daghash, S. and Ozbulut, O. E. (2021). “Tensile characterization of graphene nanoplatelet/shape memory alloy/epoxy composites using digital and thermal imaging.” Polymer Composites, 42(3), 1235-1244, https://doi.org/10.1002/pc.25896, March 2021.

- Shi, F., Zhou, Y., Ozbulut, O. E., and Cao, S. (2021). “Development and experimental validation of anchorage systems for shape memory alloy cables.” Engineering Structures, 228, 111611, 1-13, https://doi.org/10.1016/j.engstruct.2020.111611, February 2021.

- Toker, G. P., Saedi, S., Acar, E., Ozbulut, O. E., and Karaca, H. E. “Loading frequency and temperature-dependent damping capacity of NiTiHfPd shape memory alloy.” Mechanics of Materials, 150, 103565, 1-8, https://doi.org/10.1016/j.mechmat.2020.103565, November 2020.

- Sherif, M., and Ozbulut, O. E. (2020). “Thermomechanical and electrical response of a superelastic NiTi shape memory alloy cable.” Journal of Intelligent Materials and Structural Systems, 31(19), 229-2242, https://doi.org/10.1177/1045389X20943952, November 2020.

- Asfaw, A., Sherif, M., Xing, G., and Ozbulut, O. E. (2020). “Experimental investigation on buckling and post-buckling behavior of superelastic shape memory alloy bars.” Journal of Materials Engineering and Performance, 29(5), 3127-3140, https://doi.org/10.1007/s11665-020-04815-9, May 2020.

- Toker, G. P., Saedi, S., Acar, E., Ozbulut, O. E., and Karaca, H. E. (2018). “Shape memory behavior of Ni40.3Ti39.7Hf15Pd5 and Ni40.3Ti44.7Hf10Pd5.” Journal of Alloys and Compounds, 763, 1012-1017, https://doi.org/10.1016/j.jallcom.2018.05.029, September 2018

- Sherif, M., and Ozbulut, O. E. (2018). “Tensile and superelastic fatigue characterization of NiTi shape memory cables.” Smart Materials and Structures, 27 (1), 015007, 13 pages, https://doi.org/10.1088/1361-665X/aa9819, January 2018.

- Daghash, S., and Ozbulut, O. E. (2016). “Characterization of superelastic shape memory alloy fiber-reinforced polymer composites under tensile cyclic loading.” Materials & Design, 111, 504-512, http://dx.doi.org/10.1016/j.matdes.2016.09.034, December 2016.

- Ozbulut, O. E., Daghash, S., and Sherif, M. (2015). “Shape memory alloy cables for structural applications.” ASCE Journal of Materials in Civil Engineering, 04015176, doi: 10.1061/(ASCE)MT.1943-5533.0001457 , October 2015.

- Hamilton, R., Lanba, A., Ozbulut, O. E., and Tittmann, B. (2015). “Shape memory effect in cast versus deformation-processed NiTiNb alloys.” Shape Memory and Superelasticity, 1(2), 117-123, https://doi.org/10.1007/s40830-015-0024-1, June 2015.

Find more HERE.

Related Projects

Multifunctional composites for sustainable infrastructure

Project Title: Multifunctional composites for sustainable civil infrastructure systems

Project Duration: 08/01/2016 – 08/31/2018

Sponsor: Mid-Atlantic Transportation Sustainability Center (MATS)

Multi-hazard resilient design of buildings

Project Title: Multi-hazard resilient design of buildings with high strength and damping capacity shape memory alloy

Project Duration: 10/01/2015 – 09/30/2018

Sponsor: National Science Foundation (NSF)

Smart concrete bridge girders

Project Title: Smart concrete bridge girders using shape memory alloys

Project Duration: January 2013 – December 2014

Sponsor: Mid-Atlantic Universities Transportation Center (MAUTC)