The University of Virginia’s Department of Materials Science and Engineering has welcomed three new Olsen Fellows to its Ph.D. program: budding metallurgists Victor Kontopanos, Keithen Orson and Christian Walters.

The Olsen Fellowship was established in 2019, endowed by alumnus Greg Olsen’s $25 million gift to UVA’s School of Engineering and Applied Science.

“Talented graduate students are fundamental to the success of a research-focused department,” said John R. Scully, Charles Henderson Chaired Professor of Materials Science and Engineering and department chair. “Greg’s commitment to helping us expand our diverse community of Ph.D. students will have an enduring impact on our teaching and research missions.”

Here’s a look at the three new fellows and the research they’ll be exploring:

Victor Kontopanos

In May Kontopanos earned his Bachelor of Science degrees in chemistry and engineering physics at Randolph-Macon College in Ashland, Virginia. As an undergraduate who also minored in physics, he conducted research in materials and processes important to the nation’s transition to a hydrogen economy — specifically nickel phosphide nanoparticle synthesis to replace platinum as a catalyst for precursor chemicals.

“I like the interdisciplinary nature of materials science,” Kontopanos said. “You use chemistry, physics, even computer science for modeling. That really appeals to me. You need collaboration to solve problems together.”

Kontopanos gained practical experience through an internship with Afton Chemical Corp. before joining UVA’s corrosion science and electrochemistry research group led by Robert G. Kelly, AT&T Professor of Engineering and professor of materials science and engineering.

As Kontopanos shifts his focus from chemistry to materials engineering, he is in learning mode: He is diving into finite element modeling software, which is used to understand galvanic corrosion of multi-alloy systems, including materials such as stainless steel, aluminum and the carbon-fiber-reinforced polymers that are prevalent in aircraft joints and fasteners.

Kontopanos has started the progression of building geometries and running scans that serve in establishing boundary conditions for these materials. The modeling results will be used to improve researchers’ understanding of the materials’ corrosion rates and behavior, leading to a more accurate prediction of part failures and reduced maintenance costs.

Keithen Orson

Orson is fascinated by the tiniest of things.

“At the nanoscale, atoms have their own geometry and follow their own rules,” he said. “The rules of the macroscopic world don’t work once you get down to 10 or 100 nanometers.”

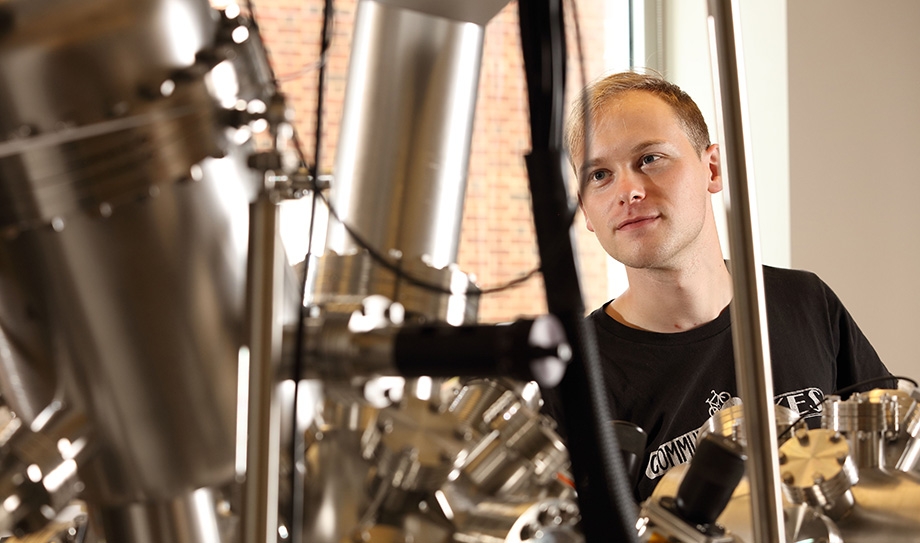

As a member of the nanomaterials and surface science research group led by Petra Reinke, professor of materials science and engineering, Orson is exploring how the micro-macro transition happens. He is also researching how oxides protect metals from corrosion by studying the growth over time of really small particles on different grains of metal. Each grain has its own landscape of atoms that grow in very different ways.

“If you have one grain that grows in a different way, is that going to make a weaker or stronger oxide?” Orson said. “Is there something we need to know about how it starts to grow that affects how it behaves later? I want to get to the bottom of these questions.”

Orson is on familiar ground, having earned his Bachelor of Science in chemical engineering from UVA in 2018, with a minor in materials science. As an undergraduate, he worked alongside graduate students advised by Reinke and Stephen McDonnell, assistant professor of materials science and engineering.

Orson discovered his passion for teaching as an assistant for a material science class. After graduation, he joined the AmeriCorps program, teaching math and science at a middle school in Washington, D.C., and helping students on the robotics team learn how to code.

He also worked briefly as a patent examiner. While he is thankful for this learning experience, Orson knew he wanted to pursue work that would have a more direct impact.

“Rather than watching technologies come and go across my desk, I wanted to actively do something about that,” Orson said. “I want to believe my work will affect the world in a meaningful way. Twenty years from now, I want to look back and know that the things I’m doing now mattered.”

Christian Walters

Walters became interested in materials science through an undergraduate class project in finite element modeling.

“The project focused on modeling the collision of a hail stone with an aluminum sheet,” said Walters, who in May earned his Bachelor of Science degree in mechanical engineering from Michigan Tech, with a minor in materials science. “I was intrigued about how the structure of the ice and aluminum affect mechanical deformation through this collision.”

Walters has set out to learn as much as he can about how a material’s structure influences its mechanical properties. He found a compatriot in UVA’s Sean R. Agnew, William G. Reynolds Professor of Materials Science and professor of materials science and engineering. Walters met Agnew and several other professors during UVA’s virtual visit day in February.

“I was struck by the welcoming environment, how enthusiastic professors are about working with students and sharing their research,” Walters said. “Professor Agnew’s standing in physical metallurgy sealed my decision.”

During the summer, Walters completed an internship with Michigan Scientific Corp., which manufactures testing equipment for the automotive industry. He conducted mechanical hardness testing experiments to verify the properties of the materials used in the firm’s products. The internship provided an on-ramp to the research Walters is pursuing in Agnew’s group.

Walters is exploring the microstructure and mechanical properties of shape-memory alloys. Specifically, he is using thermomechanical characterization techniques to measure how these alloys change their shapes in response to stress and temperature. His research will inform how these materials are processed and used commercially.

“I’m looking forward to learning as much as I can, getting started with the lab work, experimentation and modeling, to dive as deeply as possible into this research,” Walters said.