Olsen Fellows

In October 2019, distinguished alumnus Greg Olsen (MSE ’71) pledged $25 million to the University of Virginia’s School of Engineering and Applied Science to recruit and retain star faculty, support strategic initiatives and attract outstanding Ph.D. students. The Department of Materials Science and Engineering has dedicated $10.5 million from this historic gift for Olsen graduate fellowships.

The fellowships enable Ph.D. students to hone their skills and accelerate their drive for discovery while gaining exposure to modern research problems with a broad understanding of practical applications. “Talented graduate students are fundamental to the success of a research-focused department,” said John R. Scully, Charles Henderson Chaired Professor of Materials Science and Engineering and department chair. “Greg’s commitment to helping us expand our diverse community of Ph.D. students will have an enduring impact on our teaching and research missions.”

Meet the Olsen Fellows

Laura Doumaux

Laura Doumaux is a member of the advanced high-temperature materials research group led by Professor Elizabeth J. Opila. Doumaux works on multi-component rare earth silicates, used in environmental barrier coatings that protect jet turbine engines.

Doumaux connected with Opila through her network at Rolls-Royce. Opila, a professor of materials science and engineering and mechanical and aerospace engineering, holds the Rolls Royce Commonwealth Professor of Engineering endowed professorship and serves as director of the Rolls-Royce University Technology Center at UVA Engineering. Doumaux worked at the company’s Cypress, California test facility while earning her B.S. in materials science and engineering at the University of Washington.

I really like how customizable materials are,” Doumaux said. “Working with and printing enamel, I saw how customizing a material’s structure changes everything else.

In Beth’s group, we can combine elements to make new structures and optimize them for specific uses. I really enjoy that side of MSE because you can express your creativity; you can try out different things and there’s never a wrong answer.”

Outside of class, Doumaux enjoys hiking and bouldering. A self-professed foodie, Doumaux looks forward to exploring the local restaurant scene.

Sarah Beth Holles

Sarah Beth Holles studies the effects of water and oxygen on ceramic matrix composites at high temperatures. As a member of Professor Elizabeth J. Opila’s advanced high-temperature materials research group, Holles hopes to expand knowledge about CMCs and help make their use more widespread in aviation applications. Holles earned her B.S. in materials science and engineering from Michigan State University. She minored in computer science and graduated from the Honors College.

One thing that I love about MSE is the range of the field. You can do practically anything in it and that is part of what drew me to the field in the first place. It also appeals to my love of chemistry and how I can apply that knowledge to real-world problems.

Outside of class, Holles enjoys game nights with friends and playing Dungeons and Dragons and video games.

Megan Lenox

Megan Lenox, a member of the multifunctional thin film group led by Associate Professor Jon Ihlefeld, studies fabrication techniques for hafnium zirconium oxide thin films. She earned her B.S. in ceramic engineering from Missouri University of Science and Technology.

Through her research, Lenox hopes to generate a better understanding of functional materials used for electronic devices. The ferroelectric hafnium oxide material system could potentially perform computer memory functions in high-performance, low-power devices capable of solving complex mathematical problems.

I have always loved the way material science affords us the ability to gain insight into how materials behave and why,” Lenox said. “The process-property-structure relationship has always been exciting and interesting to me.

Outside of class, Lenox enjoys spending time with friends while hiking, camping and exploring Virginia.

Catherine Lynch

Catherine Lynch studies corrosion of metal alloys and how they behave in high-temperature and aqueous environments. Professors Elizabeth J. Opila and John R. Scully co-advise Lynch’s study of materials in extreme environments.

“Upon visiting the school, I realized how warm and welcoming the atmosphere was in the department,” Lynch said. “Everyone is here to build each other up, and there is a lot of collaboration between research groups.”

Lynch earned her B.S. in materials science and engineering from Alfred University, with minors in physics and chemistry.

“I really enjoyed chemistry and physics, and materials science operates on a level where there is a lot of overlap between these two fields,” Lynch said.

What I like most about materials science is seeing how even the smallest of changes can have large impacts on how a material behaves. My background is ceramics-heavy, which will help me understand oxide layers that form under different conditions and how to control the outcomes of different materials.

Outside of class, Lynch enjoys making music. “I have played the cello since elementary school and enjoy the balance it brings after a long day of work,” Lynch said.

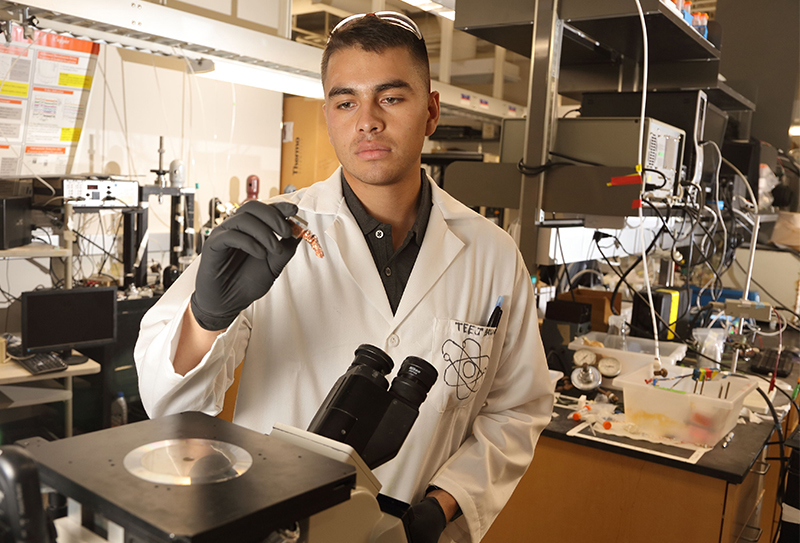

Timothy Montoya

Timothy Montoya conducts research on the corrosion properties of stainless steel and aluminum additive manufactured materials, working with Professor Rob Kelly. Montoya earned his B.S. in chemistry from the University of Mexico. Montoya conducted undergraduate research as an R&D student intern at Sandia National Laboratories, studying corrosion problems for the spent nuclear waste program—an active area of research at UVA MSE.

MSE faculty and students have joined multi-institutional teams involving universities, national labs and their private sector partners to understand and mitigate corrosion that occurs in storage containment, and to guide the selection of anti-corrosive materials for novel reactor designs. Their research advances U.S. Department of Energy initiatives, including two Nuclear Energy University Program grants and two Energy Frontier Research Centers funded by the Office of Basic Energy Sciences.

After doing corrosion research at Sandia, I grew a passion for research. This led me to pursue a material science education, so that I can contribute to solving corrosion problems in the future.

Outside of class, Montoya enjoys going to the gym, participating in sports, hanging out with friends and playing video games.

Kyle Mumm

Kyle Mumm conducts research on additively manufactured metals, working with Associate Professor Tao Sun. Mumm creates complex alloys and functional gradient structures using directed energy deposition. Mumm uses operando synchrotron x-ray imaging and diffraction techniques to investigate how the materials’ composition and the manufacturing conditions affect the generation of defects, as well as rapid solidification and phase transformation during the printing process.

“I’ve always enjoyed engineering solutions to problems, but I’m a huge fundamentals-first type of person,” Mumm said. “I couldn’t consider other engineering studies without starting at the small scale. My interest only grew as I learned more and more about the massive impacts that micro-changes can have on a material, and I’ve wanted to learn more about how I can apply that knowledge to real-world systems.”

Mumm earned his undergraduate degree in nanoengineering at the University of California, San Diego. As an undergraduate, Mumm spent a summer working on additively manufactured ceramic lattices with Lorenzo Valdevit, a professor at the University of California, Irvine.

“I found additive manufacturing to be an exciting research topic, and my search for a graduate program eventually led to UVA,” Mumm said.

One of the great things about additive manufacturing is how incredibly diverse its applications are. I’m not sure how optimized metal alloys or gradients might be best applied, but I’m very curious to see where they might up in 20 years.

Outside of class, Mumm enjoys reading, recreational level sports and puzzle games.