Nanocellular Materials

My research focuses on formulating a method for the production of bulk ordered foams. The voids in these ordered foams will be uniform in size and shape and ordered in a close packed configuration like a face centered cubic (FCC) or hexagonal close packed (HCP) atomic crystal structures. These ordered foams or inverse opals (IOs) are of interest primarily for structural applications, but the IOs and the ordered scaffold used to create them are also of interest for photonic applications. This research is primary interested in production for structural applications as a nickel IO is only 24% dense but 10 times stronger than bulk nickel!

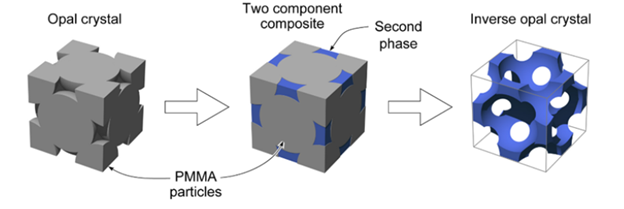

The process for creating this magnificent material on a scale useable for structural applications has three main steps shown in Figure 1. The first step is ordering uniform spheres of in to a FCC or HCP configuration, also known as an opal as natural opals are made of ordered silica spheres. These opals are made of spheres made of silica or polymers such as PMMA or polystyrene with uniform diameters from 30 µm in diameter down to 400 nm or less, making the task of ordering the sphere extremely difficult. Methods such as molds, vibration, electrophoretic deposition, shear ordering via rolling or using a doctor blade, as well as methods of evaporative ordering have been used and will be explored to order the spheres in bulk. With the spheres ordered in to an opaline configuration the voids in between the spheres are filled with a secondary material often through a polymerization, sol-gel process, or electrodeposition. This creates a unique composite material, but not quite an IO. The third and last step is to remove the initial opal scaffold via dissolution or vaporization. Removing the base opal leaves behind the IO that is desired. Overall, this sounds fairly simple, but the ordering of the spheres on a large scale is difficult as you want literally billions of spheres that don’t care where they are to all align into a perfect opal that is configurationally unique compared to the disordered spheres that has effectively infinite configurations.

Figure 1: The three steps of creating IOs. From left to right, the creation of the opal, then the deposition of the IO material, and lastly the removal of the opal scaffold to reveal the IO.

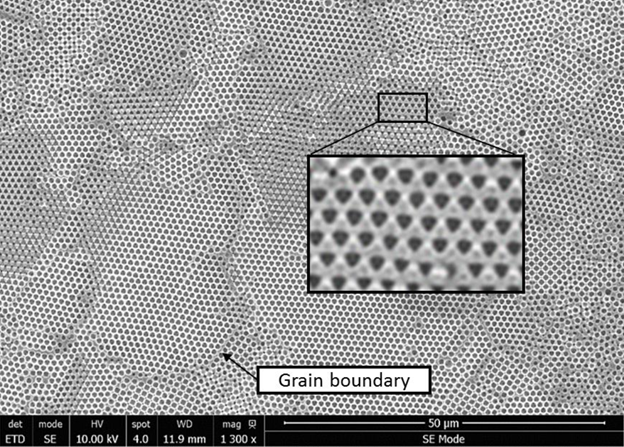

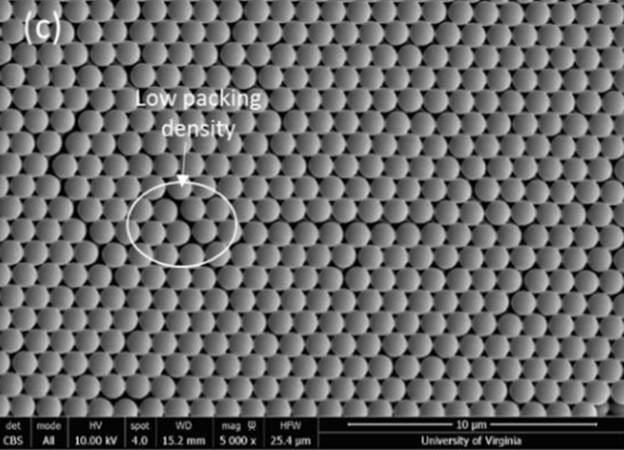

Below in Figure 2 and 3 are images of the ordered opal and IO respectively. It is observed in these examples ordering of the spheres is often only somewhat short ranged and even when there is ordering they may not pack as closely as is desired. Every defect in the base opal is transferred to the IO and Figure 3 does a good job of demonstrating how small areas inside grains of the inverse opal can look perfect but overall there are major defect in the bulk IO.

Figure 2: A scanning electron image of silica spheres ordered into an opal structure with packing defects.