Directed Vapor Deposition

The experimental physical vapor facilities utilized by the Wadley group consist of three patented processes: Directed Vapor Deposition (DVD), Biased Target Ion Beam Deposition, and Coaxial Plasma Deposition.

The experimental physical vapor facilities utilized by the Wadley group consist of three patented processes: Directed Vapor Deposition (DVD), Biased Target Ion Beam Deposition, and Coaxial Plasma Deposition.

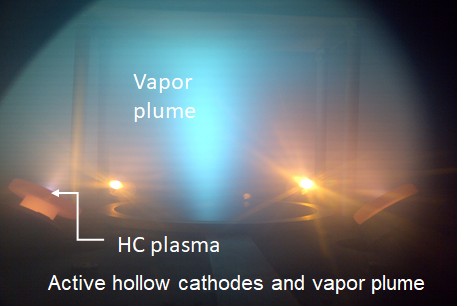

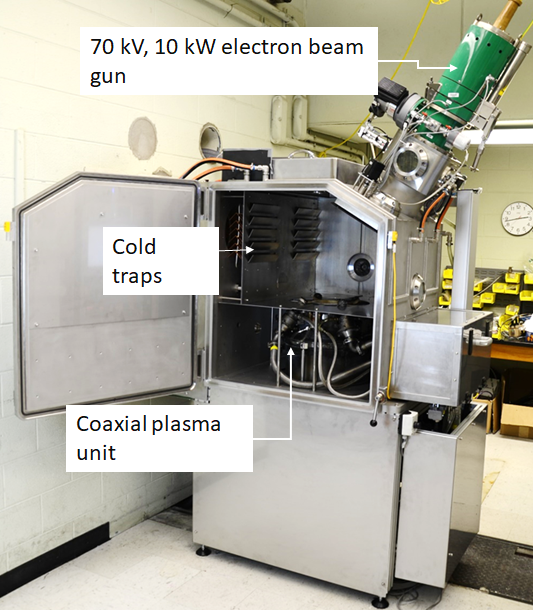

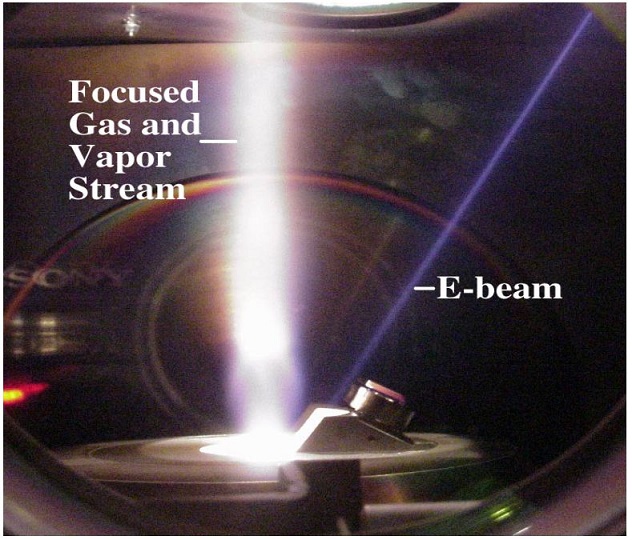

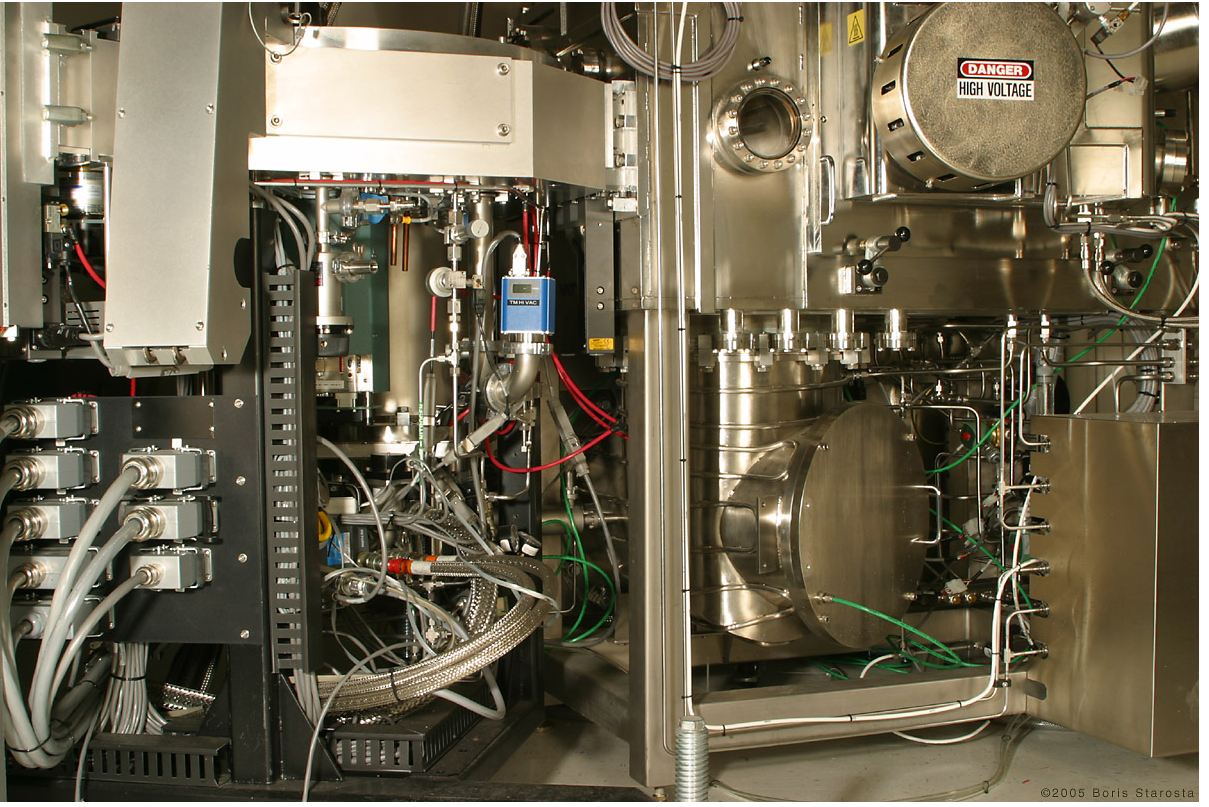

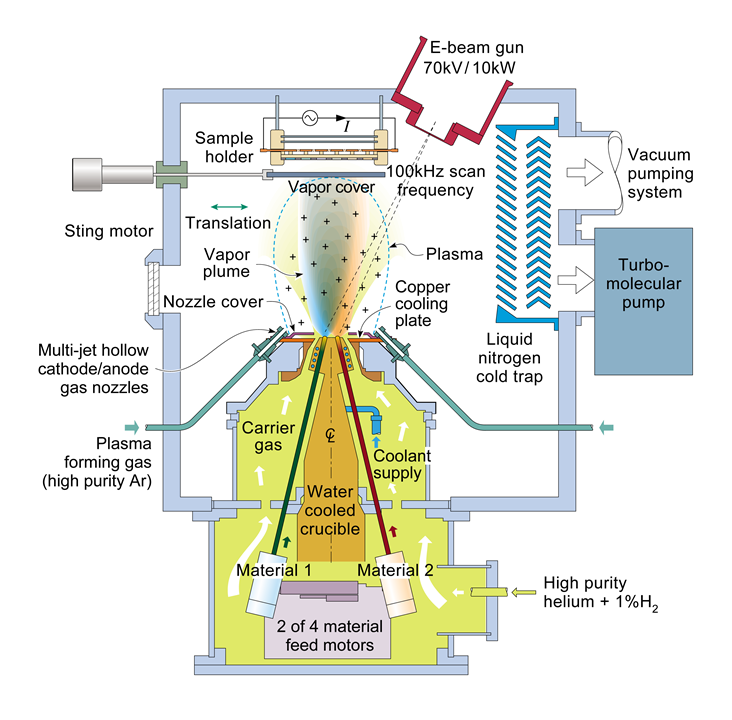

Each of the DVD systems utilizes an electron-beam (e-beam) gun to vaporize materials. Both systems use specially modified axial guns that allow creation of atomistic or molecular vapor in a low vacuum environment making it possible to entrain the evaporant in a reactive or inert supersonic gas jet. A photograph of one of the systems is shown below. A second photograph shows electron beam evaporation and entrainment in a supersonic gas jet. A plasma generation system has been integrated in to the system and can be used to modify the structure and composition of coatings. Current projects are exploring the deposition of thermal barrier coating systems, thin film capacitors, solid state batteries, solid oxide fuel cell electrode assemblies and coatings on fibers and the trusses of cellular materials. More information about the process and its applications can be found in various publications.

Directed Vapor Deposition System

The gas jet entrained vapor plume within the second generation of Directed Vapor Deposition

Biased Target Ion Beam Deposition

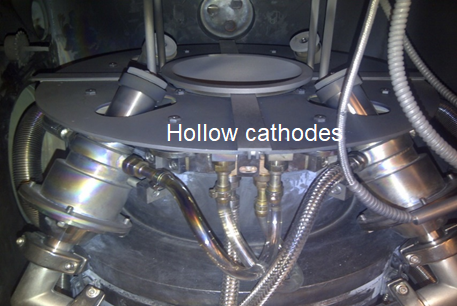

We have developed a state of the art BTIBD system using atomistic and vapor transport models. The approach is based upon the use of a very high ion density, low voltage plasmas to sputter up to six target materials sequentially. The ions used for sputtering make normal impact with the target resulting in a very low flux of high energy reflected neutral atoms. The use of a low voltage reduces the kinetic energy of the sputtered metal atoms, enabling the deposition of metal superlattices (multilayers) with very little intermixing at the interfaces. The assembly of these atoms on a substrate is manipulated using a low voltage ion assistance system. A photograph of the UVA facility is shown below.

Biased Target Beam Deposition System

Coaxial Plasma Deposition