Furnaces

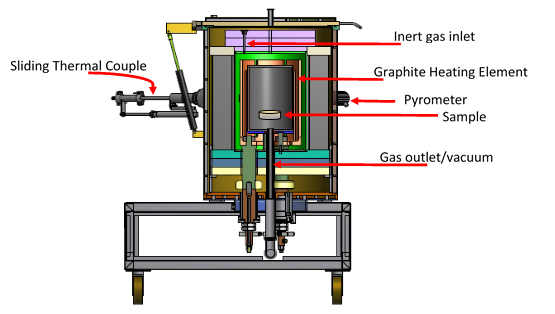

Recently, the Wadley Research Group acquired a Laboratory High-Temperature Graphite (Model LHTG 200-300 Carbolite Gero) furnace with both vacuum and inert atmosphere operating conditions. A maximum temperature of 3000°C can be achieved in argon and a maximum temperature of 2200°C can be used in a vacuum. The LHTG can achieve vacuum levels of 10-6mbar with its two-stage vacuum system consisting of a rotary vane pump and a turbomolecular pump. The heating area of the furnace has a diameter of 200mm and a height of 300mm. The cylindrical heating retort is surrounded by the graphite heating element and graphite insulation. The heating chamber is water-cooled; keeping the outside temperature of the furnace no higher than 30°C at maximum temperature. The inside temperature is detected by a thermal couple up to 900°C. After this temperature is achieved, the thermal couple automatically slides out of the system and a pyrometer will continue to control the furnace. The furnace also comes equipped with overpressure valves that will automatically release when the chamber exceeds pressures of 100bar. To ensure the purity of the system, the system has been upgraded with heated exhaust tubing and an afterburner to burn off any volatile gases. The LHTG also comes equipped with a Eurotherm controller, Siemens digital interface, and pneumatic valves. The Eurotherm controller allows for systematic heating profiles with ramp rates as quick as 1000°C/hour or as slow as 1°C/hour.

The LHTG can be used to process materials at high temperatures. Specifically, the LHTG was designed to fabricate ceramics from preceramic polymer materials. The heated tubing, afterburner, inert atmosphere, and high-temperature capabilities allow for the conversion of the preceramic polymer into a ceramic component. However, the furnace is not limited to only these capabilities. The LHTG can be used for processing materials that only can be fabricated at temperatures in excess of 2000°C.