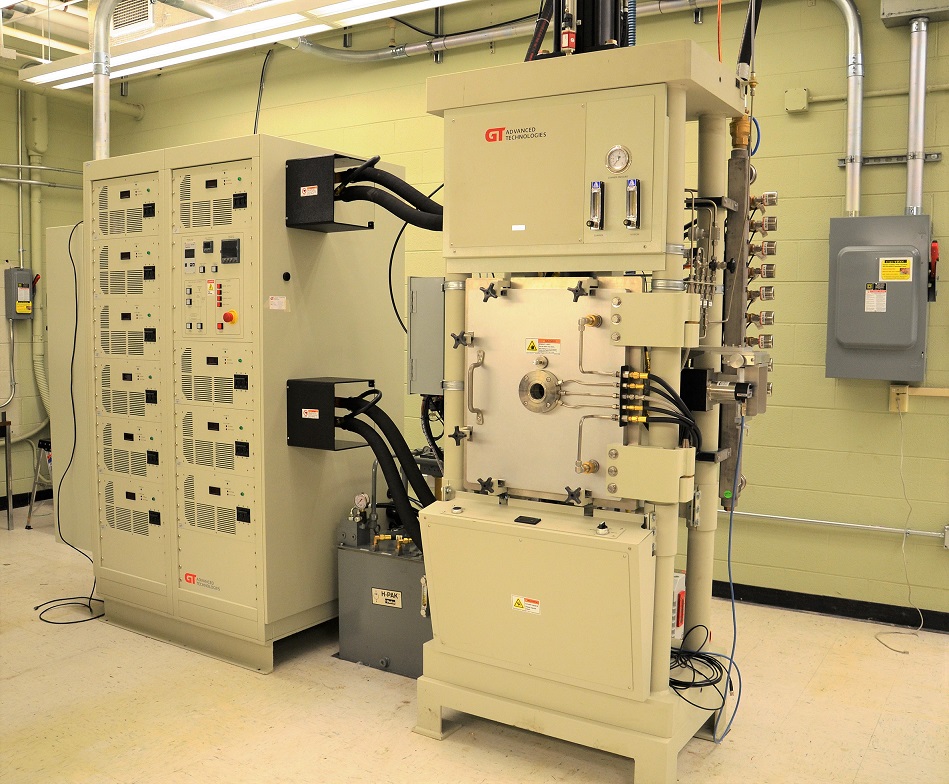

Spark Plasma Sintering (SPS)

The UVA SPS system used to explore the synthesis of high-performance ceramics, advanced composite materials and functionally graded materials (FGMs) for use in the aerospace, defense, power generation, automotive, and other applications.

The SPS system located in the IPM lab, GT Spark Plasma Sintering (SPS) system (SPS 25-10), can provide a maximum 25 tons force on the tooling dies, with the maximum operating temperature of 2200°C, with an ultimate vacuum level as low as 10 -3 Torr. The SPS utilizes high amperage (up to 10,000 amp) DC current for quick and even thermal processing, and can quickly process conductive, non-conductive and composite materials, including nanomaterials, to any level of density with high homogeneity at lower operating costs. The SPS system can also be utilized to develop thermoelectric generators for automotive applications, fuel cell materials, high strength wear resistant toolling, sputter targets, diamond compaction for abrasives and the development of pure or mixed metallic, ceramics or cermets where maintaining nanometric and fine microstructure is required. The SPS system includes remote PC-based programming station with real-time editing of waveform, force and temperature profile, high-speed proportional valves for ultra-fine hydraulic force control, and fully programmable modular power supply, including mid-process waveform multi-step adjustability.