Resistive Heating System

Resistive Heating System

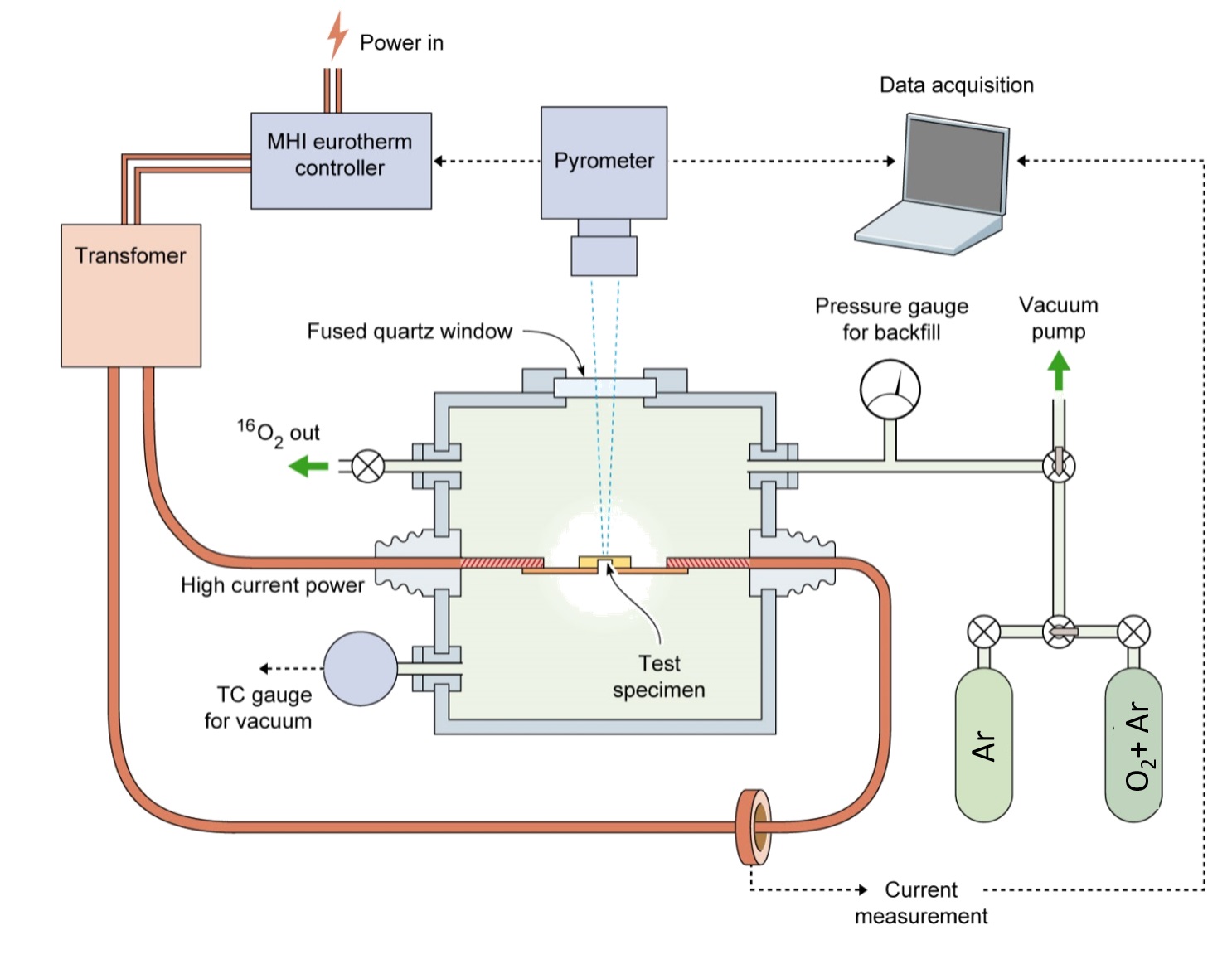

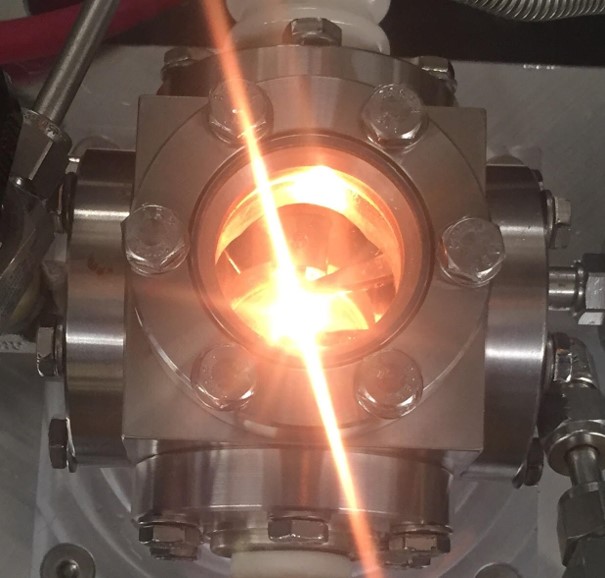

This system passes high currents (~100Amps) through the sample to heat them to ultra-high temperatures. Temperatures as high as 2000°C can be achieved. The temperature of the sample is measured using an emissivity correcting pyrometer. Both temperature and current are recorded by a computer, which uses feedback from the pyrometer to control the current flow. Control of atmosphere is possible through the use of a vacuum pump and a series of valves, allowing for the purging and back-filling of the chamber. The chamber's small volume allows for less use of expensive gases (such as 18O2 as used in double-oxidation experiments). The dog-bone shape of the samples (seen below) limits heating to the thinned section and prevents contamination of the hot part of the sample due to contact with the chamber supports. This system is currently being used to explore the ultra-high temperature oxidation resistance for a novel class of materials: high entropy ultra-high temperature ceramics.

A new and improved resistive heating system has been designed that operates at higher temperatures and has a more refined gas control system. This gives the Opila Lab the capability to generate a plasma beam made from oxygen which can help to simulate the oxygen separation effect on the leading edge of hypersonic aircraft.