UHTCs

Ultra-High Temperature Ceramics (UHTCs) for Hypersonic Vehicles

UHTC materials have possible future applications as thermal protection systems for the wing leading edges of hypersonic reentry vehicles due to their very high melting temperatures and low density. These applications experience extremely high temperatures, leading to rapid oxidation kinetics, being quantified in the Advanced High Temperature Materials lab.

UHTCs

Ultra-high temperature ceramics (UHTCs) are engineering ceramics being considered for use in a variety of extreme environment applications, such as wing leading edges of hypersonic vehicles and rocket nozzles. Their extremely high melting points make them highly attractive for these environments. However, these materials also exhibit rapid oxidation rates in the environments for which they are being considered. The Opila lab seeks to investigate the oxidation mechanisms of these materials and provide new avenues for UHTC material design.

ZrB2-SiC

The kinetics and morphology of oxides which form on ZrB2-SiC at temperatures from 1300-1900°C have been studied. Double-oxidation studies characterized using Time-of-Flight Secondary-Ion Mass-Spectrometry (TOF SIMS) provided insight into the oxidation mechanisms and pathways, and ICP-OES characterization enabled determination of the chemical composition of the glassy oxide layer.

High Entropy UHTCs

A novel approach to the design of UHTCs is currently being explored in a multidisciplinary university research initiative (MURI) titled "The Science of Entropy Stabilized High Temperature Materials" funded by the Office of Naval Research. The oxidation resistance of candidate high entropy UHTC carbides and diborides is being investigated at 1500°C and above, and at low partial pressures of oxygen, using the resistive heating system. The composition (HfZrTiTaNb)C and (HfZrTiTaNb)B2 are of particular interest. Thermodynamic modelling has been used to understand the extent of selective oxidation and provide recommendations for compositional design of high entropy UHTCs. Experimental work involves probing the time, temperature and partial pressure dependence of the extent of oxidation, oxide composition and morphology in these materials.

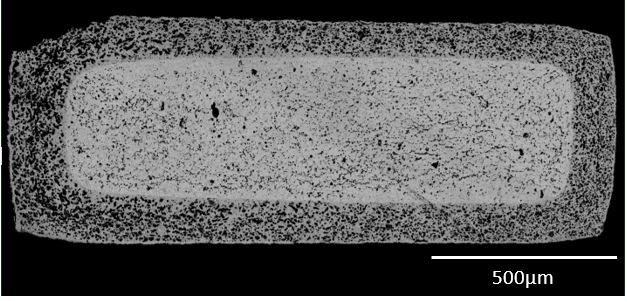

Figure 1: Cross-section back-scattered electron image of a high entropy carbide (HfZrTiTaNb)C oxidized in 1%O2 for 5 minutes at 1500°C.

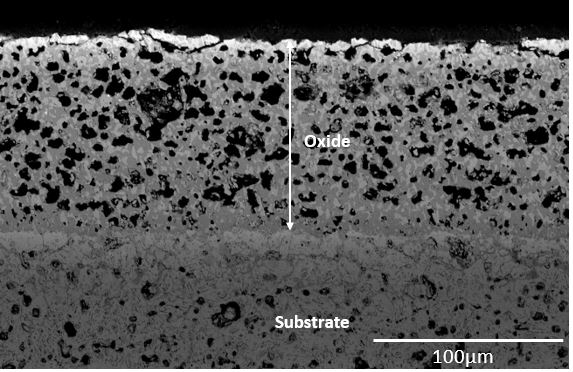

Figure 2: Higher magnification image, in cross-section, of the oxide formed on a high entropy carbide (HfZrTiTaNb)C oxidized in 1%O2 for 5 minutes at 1500°C.