Ceramic Matrix Composites

Opila High-Temperature Oxidation Behavior of SiC-based Ceramic Matrix Composites (CMCs)

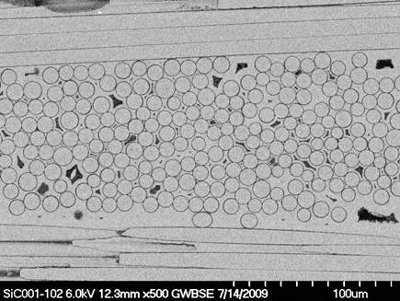

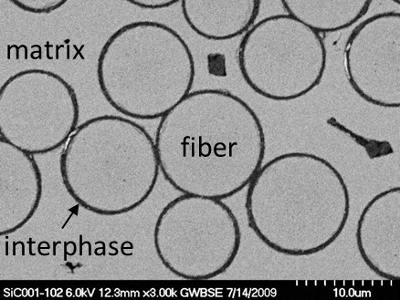

CMCs are a novel class of materials with high temperature capabilities and low densities. SiC-based CMCs have potential capability in extreme environments, such as jet turbine engines. Parts for replacement include combustion liners, nozzle flaps of afterburners, and turbine vanes/blades.

Areas of study for CMCs within the Opila research group include:

- Low and high temperature oxidation behavior of SiC/SiC CMCs utilizing DRY AND WET OXYGEN TGAS

- Coupled stress and oxidation exposures utilizing MTS Tensile Machine with environmental control

- Understanding the effects of composite chemistry and architecture on the hot corrosion of SiC/SiC CMCs

- Investigating the oxidation resistance and stability of possible CMC matrices in high temperature water vapor environments

- Working to understand the failure conditions of CMCs used in gas turbine applications due to excessive borosilicate glass formation when exposed to oxygen and water vapor

These topics will allow for insight into CMC failure mechanisms and times, thus improving future CMC materials and informing life cycle prediction models.