Steam Jet

Steam-Jet Tube Furnaces

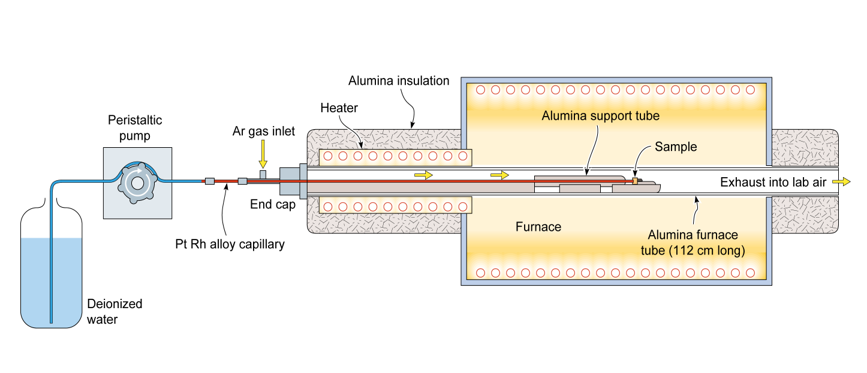

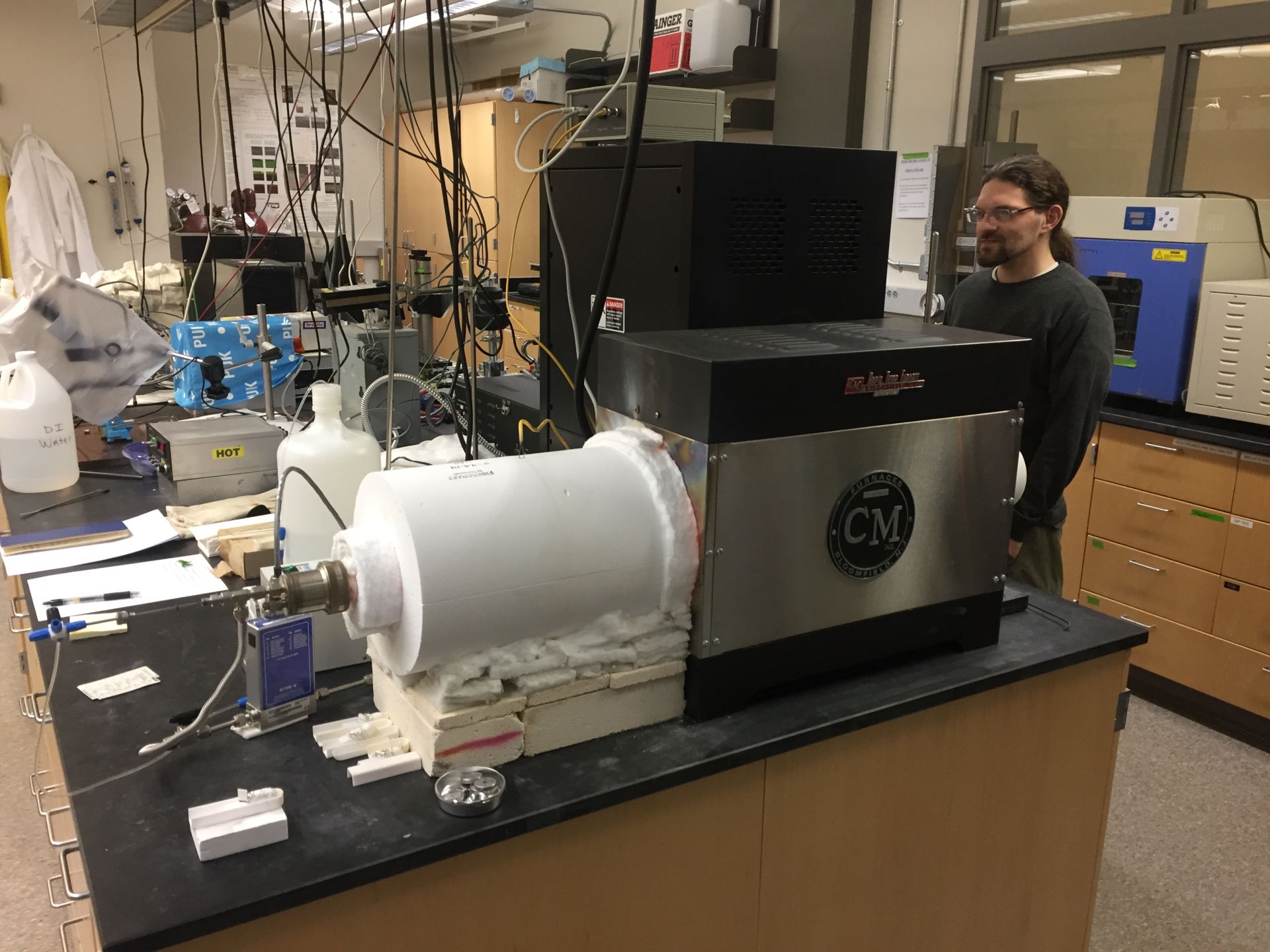

A steam-jet furnace for testing material durability was developed based on the design of dos Santos e Lucato et al. [JACerS 94 [S1] S186 (2011).] Liquid water is injected into the furnace hot zone through a small diameter capillary. The vaporization of the liquid water results in a rapid volume expansion which creates a high-temperature high-velocity steam-jet that impinges on the test sample. The steam-jet furnace design enables us to perform multiple high temperature water vapor exposure on a single sample. The sample can be placed in the furnace for an exposure time, removed, characterized and returned to the furnace for additional exposures. Reaction rates are determined by measuring weight change and recession as a function of time.

The linked animation (CFX 1.WMV) shows the velocity profile of steam in the steam-jet leading up to, at, and downstream of the impingement site.