CMAS

Calcium Magnesium Alumino-Silicate (CMAS)

Calcium magnesium alumino-silicate (CMAS) attack is a pressing issue in the development of environmental barrier coatings (EBCs) for ceramic matrix composites (CMCs). Strategies for mitigating CMAS attack are being developed in the Opila lab.

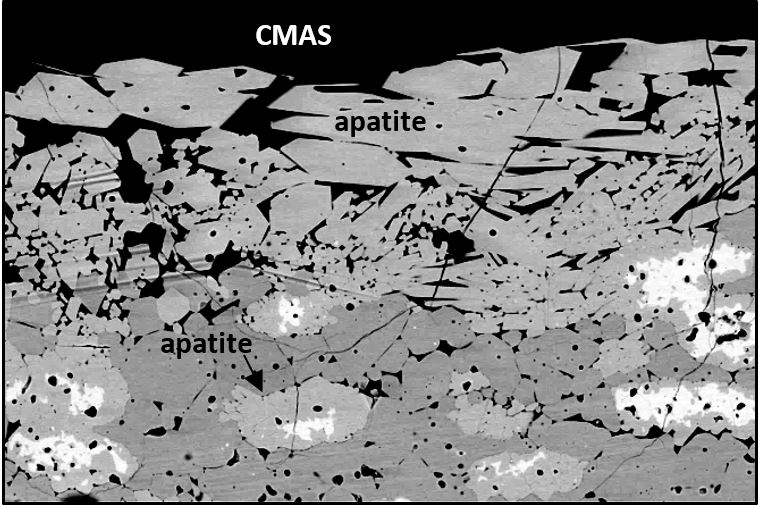

CMAS originates as siliceous debris such as sand or volcanic ash, which can be ingested into aircraft turbine engines during flight. At temperatures of ~1200°C, CMAS melts and can penetrate EBC materials, causing premature coating failure. Inducing crystallization of these glassy deposits at the coating/liquid interface has been suggested in the literature as a mitigation strategy.

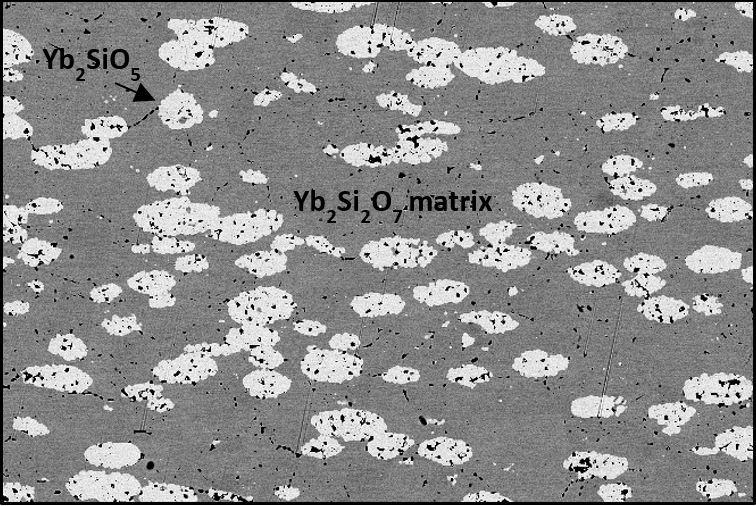

The Opila lab is investigating novel EBC materials for their resistance to CMAS. Model air plasma spray rare earth silicates having controlled compositions and microstructures have shown promising results. Inducing CMAS crystallization between coating and CMAS to form a stable crystalline phase, such assilicate oxyapatite (Ca2Yb8(SiO4)6O2), helps to limit CMAS infiltration compared to coating materials that do not react. Other EBC materials of interest include rare earth (RE) titanates and high entropy rare earth monosilicates (HEREMS).

CMAS composition, and thus glass properties, can vary widely based on source and location. Glass melting temperature and viscosity are important parameters to consider when addressing coating infiltration; however, there is little experimental data on the viscosity of CMAS melts. The Opila lab has the capability to obtain experimental viscosity values for CMAS glasses of variable composition using a high temperature rotating spindle viscometer. CMAS infiltration tests between different CMAS compositions and EBC materials are also performed to elucidate the effect of viscosity on coating infiltration.