EBC-CMCs

Protective Environmental Barrier Coatings for CMCs

In order to increase the lifetime of CMCs to the desired range (approximately 20,000 hours) an environmental barrier coating (EBC) must be applied that greatly reduces the speed of degradation in this combustion environment.

SiC based ceramic matrix composites (CMCs) were put into service in commercial aircraft engines in 2016. The combustion process in a turbine engine produces a large amount of water vapor along with other particulate matter. If SiC were left exposed to this water vapor, the thermally-grown, protective SiO2 would recess due to the formation of a volatile silicon hydroxide gas, allowing water vapor to attack the bare SiC. This significantly diminishes the lifetime of these composites. In order to increase the lifetime of CMCs to the desired range (approximately 20,000 hours), a coating, called an environmental barrier coating (EBC) must be applied that greatly reduces the speed of degradation in this combustion environment.

Current research is being carried out on several silicate systems: ytterbium and yttrium disilicate, hafnium silicate or Hafnon, and BaSrAlSi2O8 (BSAS). These coatings are studied in the phase pure and air plasma spray (APS) formats, by exposing them to high temperature, high velocity steam in the steam-jet furnace for 125+ hours.

High velocity steam (150-200 m/s) will impinge on the material surface. Characterization will center around XRD and SEM/EDS to understand microstructure changes with respect to time (0 - 250 hours) and temperature (1200C-1400C) for the various EBC candidates. Rate limiting factors controlling silica depletion, such as coarsening and sintering of product oxide, will be identified. By understanding and controlling the microstructure changes within environmental barrier coatings, we hope to increase the effectiveness of EBCs and create more accurate lifetime prediction models for future EBC materials.

In the case of RE disilicate (RE2Si2O7) coatings, transformation to monosilicate (RE2SiO5) occurs by reaction of SiO2 with water vapor. This is the same reaction that occurs in the SiO2 that grows on SiC, but the activity of SiO2 is an order of magnitude lower in RE silicate coatings compared to pure SiO2 making the recession of SiO2 much slower.

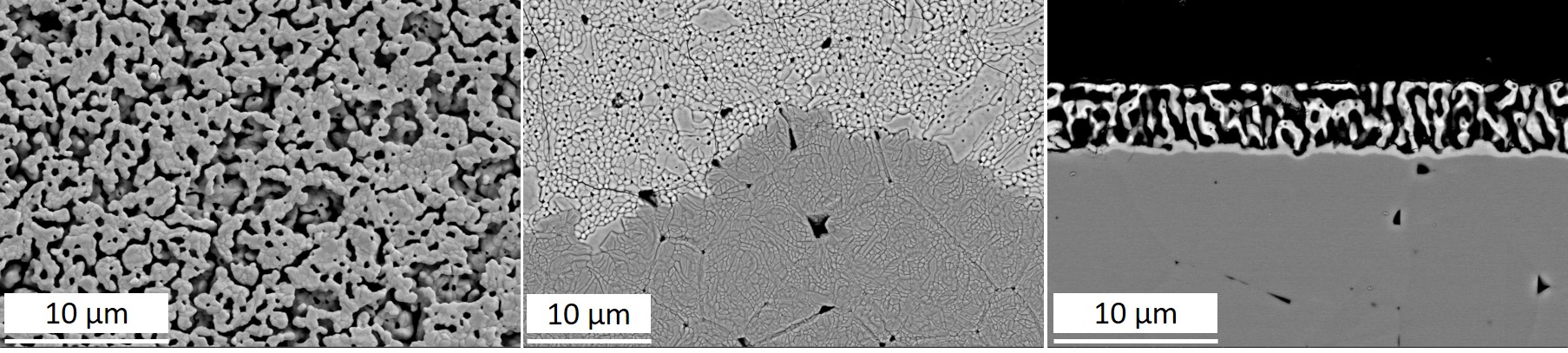

Ytterbium disilicate exposed in the steam-jet furnace for 125 hours:

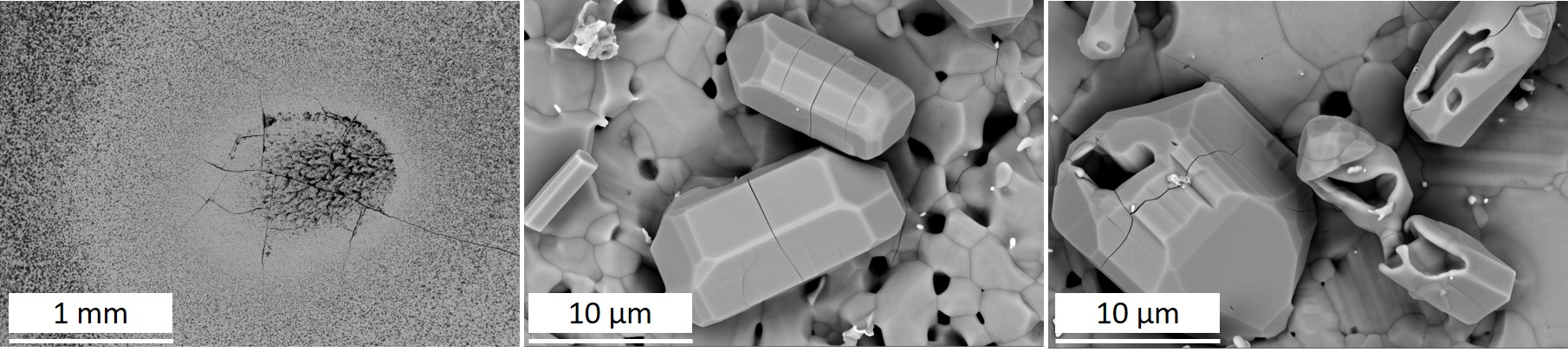

Barium strontium aluminosilicate (BSAS) exposed in the steam-jet furnace for 125 hours:

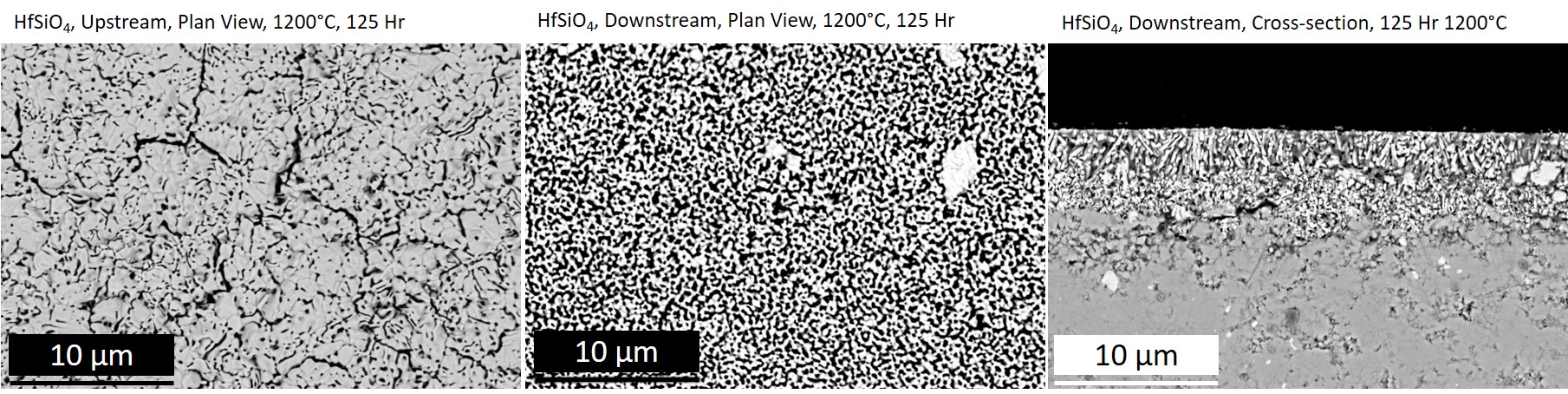

Hafnium silicate (Hafnon) exposed in the steam-jet furnace for 125 hours:

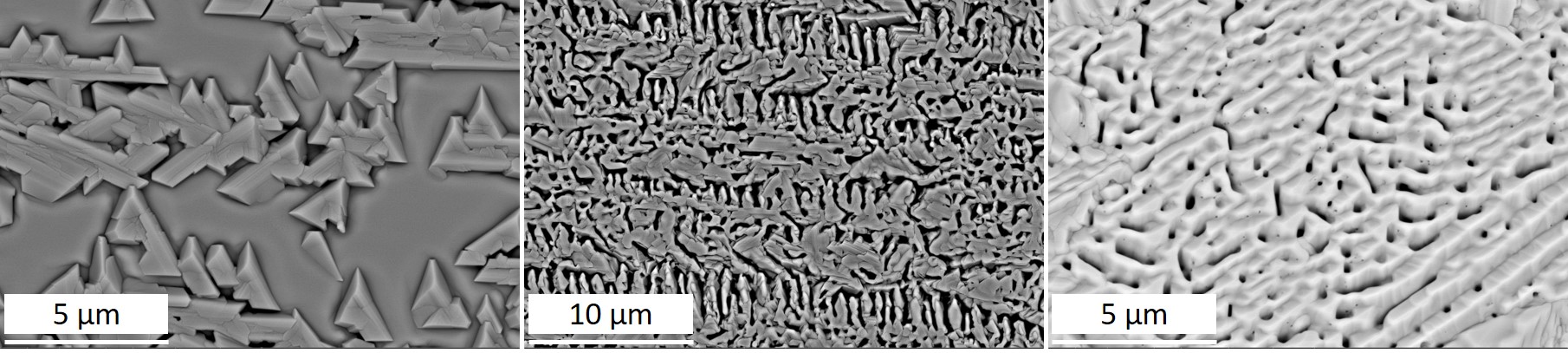

Single crystal silicates exposed in the steam-jet furnace:

-

Time: 5:00 PM - 6:00 PMLocation: Olsson 009

-

Time: 9:00 AM - 10:30 AMLocation: Online